Exhaust gas flow from a gas turbine is 250,000 lb/h at 1000°F. Gas analysis in percent by volume (vol %) is CO2 = 3, H2O = 7, N2 = 75, and O2 = 15. Superheated steam is generated at 600 psia at 875°F, and about 20,000 lb/h of saturated steam is required for process, which is taken off the steam drum. Predict the HRSG gas/steam profiles. Use 20°F pinch and approach points, 230°F feedwater, and 1% blowdown and heat loss.

In the off-design mode, process steam is not required. Steam pressure is 650 psia. Determine the HRSG performance. Steam temperature is uncontrolled.

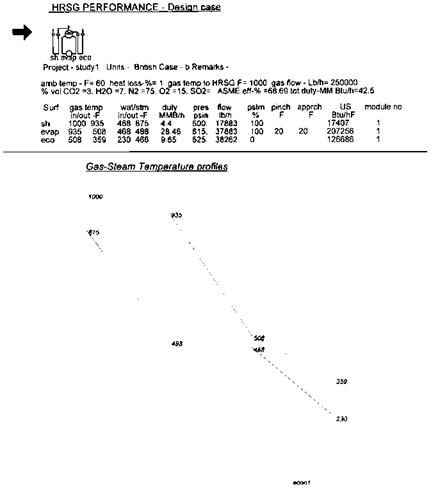

Solution. The design mode run is shown in Fig. 1.16a. The evaporator generates 37,883 lb/h, and 17,883 lb/h is sent through the superheater as

20,0 lb/h is taken off for process from the drum.

In the off-design mode, almost all of the steam, 35,270 lb/h, is sent through the superheater. As a result the steam temperature is lower, only 749°F, as shown in Fig. 1.16b. Note that without the program it would be tedious to perform this

|

Svphtrl n.api Figure 1.16a Performance of a HRSG with process steam use. |

Project • study 1 Units — BRITISH Case — b Remarks ■

![]()

![]() Amb temp — F= 60 heat IOSS-%= 1 gas temp to HRSG F= 1000 gas flow — LWh= 250000 % vol C02 =3. H20 =7. N2 =75 02 =15. $02= AS ME eff-% =67 22 totduty-MM Btu/h=41.6

Amb temp — F= 60 heat IOSS-%= 1 gas temp to HRSG F= 1000 gas flow — LWh= 250000 % vol C02 =3. H20 =7. N2 =75 02 =15. $02= AS ME eff-% =67 22 totduty-MM Btu/h=41.6

TOC o "1-5" h z Surf gas temp wat/stm duty pres How pstm pinch apprch US module no in/out-F in/out-F MMB/h psia Ib/h % F F Btu/hF sh 1000 909 503 749 6.1$ 650. 35270 100 19210 1

Evap 909 521 486 503 25 73 698.5 35270 100 17 17 206829 1

Eco 521 370 230 486 9.68 706.5 35623 . 127179 1

1000

909

|

|

370

‘ 230

Figure 1.16b Performance of the HRSG when process steam is not required.

Calculation, because we have no idea of the exit gas temperature in the design mode.

14 июля, 2013

14 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике