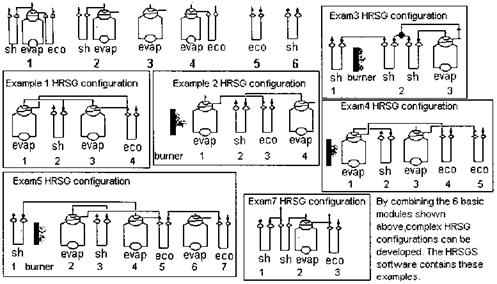

I have developed a simulation program called HRSGS to perform these complex design and off-design performance calculations. Basically the desired HRSG configuration is built up by using the six basic modules shown in Fig. 2.19. By using the common economizer or common superheater concept, one can configure complex multiple-pressure HRSGs, as shown in the examples in the figure. Up to 10 modules or nine pressure levels can be evaluated. The program automatically arrives at the firing temperature and the fuel requirement if the desired steam quantity is known with both turbine exhaust and fresh air cases. It checks for steaming in the economizer and handles import or export steam from evaporators as illustrated by a few examples in Chapter 1 (See p. 26 and 36). It

|

FIgure 2.19 How basic modules may be combined to arrive at complex HRSG configurations. |

Computes the ASME efficiency and prints out the US values for each surface in the design and off-design modes as shown in several examples in Chap. 1.

The simulation program is generally used for convective-type HRSGs and waste heat boilers, which operate on clean gas streams. If a radiant furnace is used, there will be some variation between the actual and predicted values. Because of the large fouling factors involved in dirty gas applications, the heat transfer coefficients cannot be corrected for off-design conditions accurately; hence there will be some deviation between predicted and actual performance if this is used in, say, municipal waste applications. For more information about the program, please contact the author at V_ganapathy@yahoo. com or visit the web site http://vganapathy. tripod. com/boilers. html

22 июля, 2013

22 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике