The principle of dust collection in a WS is different from that of the previous three methods. Instead of directly separating the dust from the flue gas, the dust is merely diverted from the flue gas to the scrubbing liquid, and thereby the gases are freed from the dust burden. Wet scrubbers use a fine spray of water or process liquid onto the dusty gas stream to allow intimate contact of the dust and the liquid. The heavier liquid particles, impinge on the dust and retain dust in the liquid stream, whereas the cleaned gases escape. The effluent ash-liquid mixture in a slurry form is subsequently treated and discharged.

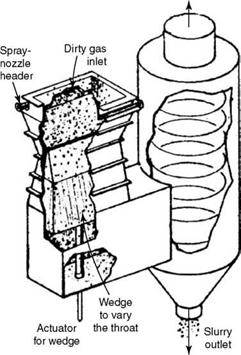

There are several variations in WS. The most common type is the Venturi scrubber with variable orifices, which is a very efficient dust retainer.

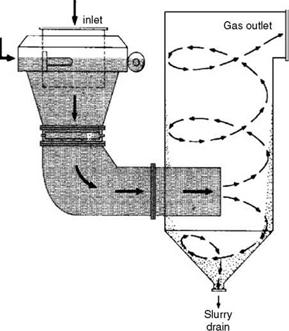

1. Venturi: gases are accelerated into a narrow channel and the liquid is sprayed to create the intimate contact.

2. Cyclone: remaining dust is hurled toward the walls by centrifugal force and trapped by the wall flow.

The process, with two stages of collection, is very efficient but energy-intensive. Power is spent in accelerating and rotating the gases and also in spraying and recirculating the liquid. As the dust is usually acidic, the effluent slurry needs to be treated before disposal.

Figures 8.42 and 8.43 show the Venturi scrubber. The flue gas is accelerated to 30-60 m/s and the total pressure drop is varied from 100 to 800 mm wg, depending on the gas volume, particle size, dust loading, and the required collection efficiency. The adjustable throat makes it possible to control these parameters.

• Very high levels of dust loads and high gas temperatures are treatable in wet scrubbers.

• Very high collection efficiencies of >99.9% are possible.

Clean gas outlet

|

FIGURE 8.42 Isometric view of Venturi scrubber. (From Power magazine. With permission.) |

|

|

|

|

|

|

|

• Collection efficiency and power consumption can be varied by throat adjustment.

• Collection of particles as small as 0.2 |jm is possible.

• The equipment is extremely simple and has no moving parts.

• The floor space required is very small.

• Maintenance is easy and inexpensive.

• The power consumption is great. Depending on the collection efficiency, the draft loss across the scrubber varies from 100 to 800 mm wg. Sizable power is involved in the spraying of liquid in the Venturi and recirculation in the cyclone.

• The effluent is wet slurry.

• Only for the biofuels with no sulfur, the slurry is not acidic and may escape with light treatment. Otherwise, the slurry is acidic with attendant disposal problems.

• The scrubber and the downstream ducting have to be made of corrosion-resistant material such as ss 316L. The stack also needs some corrosion protection.

• For coal ash, the Venturi needs an erosion protection by way lining.

High power and effluent treatment requirements have made the WS unpopular with the utilities. This may change when the savings in real estate are factored. In process industries that have effluent treatment plants, WS does not pose new problems. For oil-fired boilers, which produce fine soot and high-carbon, WS is better suited. Biofuels, which generate light ash with burning char, and high carbon ESP and FF create other problems. A WS makes a good collector, particularly because the effluent is not acidic.

Comparison of Different Dust Collectors by Performance

Different dust collectors have different areas of applications, and no two are alike. There is an overlap in cyclones and multiclones and also ESPs and FFs. The advantages and limitations of each type have been discussed. A comparison on performance parameters of all the collectors is presented in Table 8.2.

|

TABLE 8.2 Comparison of Performance Parameters of Various Dust Collectors

|

30 августа, 2013

30 августа, 2013  admin

admin

Опубликовано в рубрике

Опубликовано в рубрике