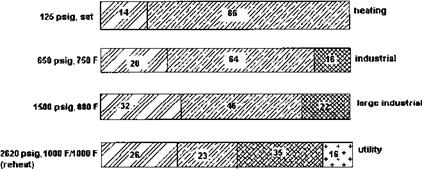

The energy absorbed by steam is distributed among feedwater heating (sensible heat), boiling (latent heat), superheating, and reheating functions. The distribution ratios are a function of steam pressure, as can be seen from steam tables or from Fig. 3.6. If the latent heat is large as in low pressure steam, a large furnace is required for the boiler; as the pressure of steam increases, the latent heat portion decreases and the superheat and reheat energy absorption increases. The boiler design accordingly varies with large surface areas required for the superheaters and reheaters and a small furnace with little or no convective evaporator surface in particular. The sensible heat, which is absorbed in the economizer, is also high at high pressure. The distribution of energy among the various surfaces—the furnace, evaporator, superheater, reheater, and economizer—is somewhat flexible, as will be shown later, but it must be emphasized that steam pressure plays a significant role in determining the sizes of these surfaces.

|

Sensible heat latent heat superheat reheat |

|

Figure 3.6 Distribution of energy in boilers as a function of steam pressure. |

In natural circulation units the density differential between the cooler water in the downcomers and the less dense steam-water mixture in the riser tubes of the furnace provides the hydraulic head for circulation of the steam-water mixture through the evaporator tubes. The circulation ratio, CR, which is the ratio of the mixture flow to steam flow, could be in the range of 6-8 in high pressure boilers. In packaged boilers operating at low steam pressure, say 150- 1000psig, the CR could be higher, ranging from 10 to 20. Note that we are referring to an average value. The circulation ratio will differ for each parallel circuit, depending on its length, tube size, heat flux, and static head available, as discussed in Q7.29. The controlled circulation boiler is operated at a slightly higher steam pressure, around 2500-2600 psig, and flow is ensured through the furnace tubes by a circulating pump; which forces the boiler water through each circuit. The circulation ratio is preselected in the range of about 2-4. This is done to reduce the operating cost associated with the circulating pumps; also, the use of carefully selected orifices ensures the flow of the steam-water mixture through each circuit. Hence a low CR is used in these systems. The once-through unit with superimposed circulation requires the circulating pump during start-up and at low loads when flow through the circuits is not high and later switches to the once-through mode at higher loads.

23 июля, 2013

23 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике