The terms boiler and steam generator are often used in the same context. Boilers may be classified into several categories as follows:

By Application: Utility, marine, or industrial boiler. Utility boilers are the large steam generators used in power plants generating 500-1000 MW of

|

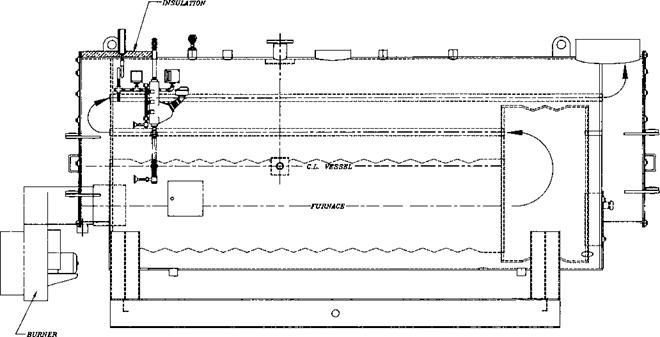

FIgure 3.3a Fire tube boiler—wetback design. |

|

|

Electricity. They are generally fired with pulverized coal, though fluidized bed boilers are popping up in some plants. Utility boilers generate high pressure, high temperature superheated and reheat steam; typical parameters are 2400psig, 1000/1000°F. A few utility boilers generate supercritical steam at pressures in excess of 3500 psig, 1100/1100/ 1100° F. Double reheat cycles are also in operation. Industrial boilers used in cogeneration plants generate low pressure steam at 150psig to superheated steam at 1500 psig at temperatures ranging from 700 to 1000° F.

By Pressure: Low to medium pressure, high pressure, and supercritical pressure. Process plants need low to medium pressure steam in the range of 150-1500 psig, which is generated by field-erected or packaged boilers, whereas large utility boilers generate high pressure (above 2000 psig) and supercritical pressure steam.

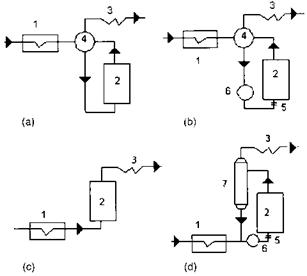

By Circulation Method: Natural, controlled, once-through, or combined circulation. Figure 3.4 Illustrates these concepts. Natural circulation is widely used for up to 2400 psig steam pressure. There is no operating cost incurred for ensuring circulation through the furnace tubes, because gravity aids the circulation process. Controlled and combined circulation boilers use pumps to ensure circulation of a steam-water mixture through the evaporator tubes. Supercritical boilers are of the once- through type. It may be noted that once-through designs can be employed at any pressure, whereas supercritical pressure boilers must be of a once-through design.

By Firing Method: Stoker, cyclone furnace, fluidized bed, register burner, fixed or moving grate.

By Construction: Field-erected or shop-assembled. Large industrial and utility boilers are field-erected, whereas small packaged fire tube boilers up to 90,000 lb/h capacity and water tube boilers up to 250,000 lb/h are generally assembled in the shop. Depending on shipping dimensions, these capacities could vary slightly.

By Slag Removal Method: Dry or wet bottom, applicable to solid-fuel-fired boilers.

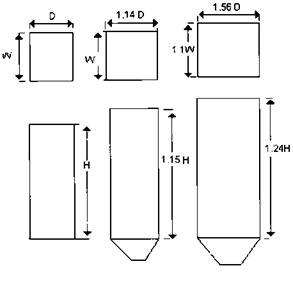

By Heat Source and Fuel: Solid, gaseous, or liquid fuels, waste fuel or waste heat. Waste heat boilers are discussed in Chapter 2. The type of fuel used has a significant impact on boiler size. For example, coal-fired boiler furnaces are large, because a long residence time is required for coal combustion, whereas oil — and gas-fired boilers can be smaller, as shown in Fig. 3.5.

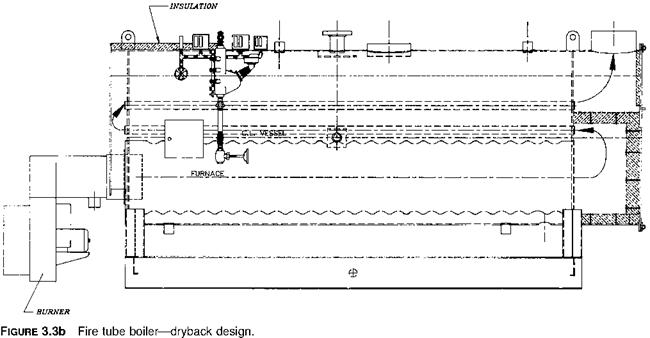

According to Whether Steam is Generated Inside or Outside the Boiler Tubes: Fire tube boilers (Fig. 3.3), in which steam is generated outside the tubes, are used in small plants up to a capacity of about 60,000 lb/h

|

FIgure 3.4 Boiler circulation methods. (a) Natural; (b) forced circulation; (c) once-through; (d) once-through with superimposed circulation. 1, Economizer; 2, furnace; 3, superheater; 4, drum; б, orifice; б, circulating pumps; 7, separator. |

|

|

GAS CV) OIL C1.31V) COAL (2.14V)

Figure 3.5 The impact of fuel on furnace size.

Of saturated steam at 300psig or less; they typically fire oil or gaseous fuels. Water tube boilers, in which steam is generated inside the tubes, can burn any fuel, be of any size, and operate at any pressure but are generally economical above 50,000 lb/h capacity. See Chap. 2 for a comparison between fire tube and water tube waste heat boilers.

23 июля, 2013

23 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике