A recent development in power generation technology is the Kalina cycle, which basically follows the Rankine cycle concept except that the working fluid is 70% ammonia-water mixture. It has the potential to be 10-15% more efficient than the Rankine cycle and uses conventional materials of construction, making the technology viable. Figure 1.4 Shows the scheme of the demonstration plant at Canoga Park, CA, which has been in operation since 1995 [4-6]. In the typical steam-water-based Rankine cycle, the loss associated with the working fluid in the condensing system is large; also, the heat is added for the most part at constant temperature; hence there are large energy losses, resulting in low cycle efficiency.

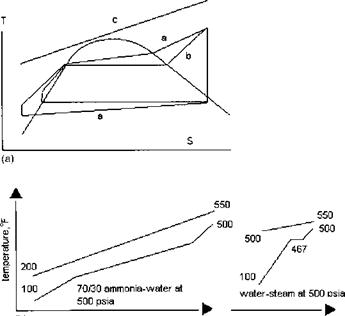

In the Kalina cycle, heat is added and rejected at varying temperatures (Fig. 1.7a), which reduces these losses. The steam-water mixture boils or condenses at constant temperature, whereas the ammonia-water mixture has varying boiling and condensing temperatures and thus closely matches the temperature profiles of the heat sources. The distillation condensation subsystem (DCSS) changes the concentration of the working fluid, enabling condensation of the vapor from the turbine to occur at a lower pressure. The DCSS brings the mixture concentration back to the 70% level at the desired high inlet pressure before entering the heat recovery vapor generator (HRVG). The HRVG is similar in design to an HRSG.

The ammonia-water mixtures have many basic features unlike those of either ammonia or water, which can be used to advantage:

1. The ammonia-water mixture has a varying boiling and condensing temperature, which enables the fluid to extract more energy from the hot stream by matching the hot source better than a system with a constant boiling and condensing temperature. This results in significant energy recovery from hot gas streams, particularly those at low temperatures, such as the geothermal heat source of Fig. 1.7b. By changing the working fluid concentration from 70% to about 45%, condensation of the vapor is enabled at a lower pressure, thus

|

Figure 1.7 (a) Cycle diagram: Kalina vs. steam Rankine systems. (b) Temperature profiles of (left) Kalina and (right) steam heat recovery systems. |

Recovering additional energy from the vapor in the turbine with lower energy losses at the condenser system. As can be seen in Fig. 1.7b, the energy recovered with a steam system is very low, whereas the ammonia-water mixture is able to recover a large fraction of the available energy from the hot exhaust gases. A steam plant would have to use a multiple-pressure system to recover the same fraction of energy, but this increases the complexity and cost of the steam plant. The lower the temperature of the gas entering the boiler, the better is the Kalina system compared to the steam system.

2. The thermophysical properties of an ammonia-water mixture can be altered by changing the ammonia concentration. Thus, even at high ambient temperatures, the cooling system can be effective, unlike in a steam Rankine system, where the condenser efficiency drops off as the cooling water temperature or ambient temperature increases. The Kalina cycle can also generate more power at lower cooling water temperatures than a steam Rankine cycle.

3. The ammonia-water mixture has thermophysical properties that cause mixed fluid temperatures to change without a change in heat content. The temperature of water or ammonia does not change without a change in energy.

4. Water freezes at 32°F, whereas pure ammonia freezes at — 108°F. Ammonia-water solutions have very low freezing temperatures. Hence at low ambient temperatures, the Kalina plant can generate more power without raising concerns about freezing.

5. The condensing pressure of an ammonia-water mixture is high, on the order of 2 bar compared to 0.1 bar in a steam Rankine system, resulting in lower specific volumes of the mixture at the turbine exhaust and consequently smaller turbine blades. The expansion ratio in the turbine is about 10 times smaller. This reduces the cost of the turbine condenser system. With steam systems, the condenser pressure is already at a low value, on the order of 1 psia; hence further lowering would be expensive and not worth the cost.

6. The losses associated with the cooling system are smaller due to the lower condensing duty, and hence the cooling system components can be smaller and the environmental impact less.

10 июля, 2013

10 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике