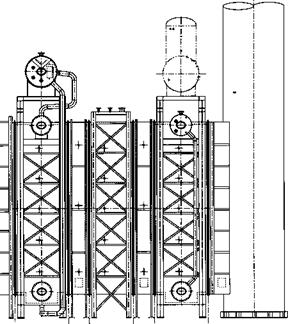

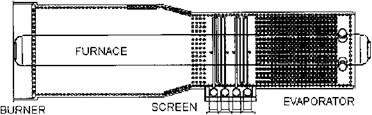

Supplementary firing is an efficient way to increase the steam generation in HRSGs. Additional steam in the HRSG is generated at an efficiency of nearly 100% as shown in Q8.38. Typically, HRSGs in combined cycle plants are unfired and those in cogeneration plants are fired. The merits of auxiliary firing in HRSGs are discussed in Q8.38. Figure 1.13 shows the arrangement of a supplementary-fired HRSG, which can handle a firing temperature of about 1600°F. Typically, oil or natural gas is the fuel used. Figure 1.14 shows a furnace — fired HRSG, which can be fired up to 3000°F. The superheater is shielded from the flame by a screen section. The furnace should be large enough to enclose the flame. In furnace-fired HRSGs even a solid fuel can be fired and the HRSG design approaches that of a conventional steam generator. Water-cooled membrane walls ensure that the casing is kept cool. A large amount of steam can be generated in this system. Table 1.6 Compares the features of unfired, supplementary-fired, and furnace-fired HRSGs.

Figure 1.13 Multipressure supplementary-fired HRSG.

|

1 I

|

|

|

Figure 1.14a Furnace-fired HRSG arrangement.

13 июля, 2013

13 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике