There are several ways of classifying boilers as shown in the following sections. The list covers most types but cannot be construed as complete.

The first classification of boilers is based on what flows through the boiler tubes.

• Fire or smoke or flue tube or shell-type boilers in which flue gases are inside and water is outside

• Water tube boilers in which water is inside and flue gases are outside

• Combination (combo boiler) in which flue gas and water flow both outside and inside the tubes; in this type contains an external furnace and shell-type boiler in a sequence

Fire tube boilers are basically suitable for

• Clean fuels such as oil and gas, since the dusty fuels cause fouling and erosion as they travel in the tubes

• Smaller sizes up to 35 tph, limited by the size of shell

• Small superheaters (SHs) of ~50°C, as there are arrangement problems for accommodating large SH surfaces

• Low pressures of usually <25 atm limited by the pressure-holding capacity of the shell

They are popular in the process industry for small steam requirement despite

1. A poorer safety record inherent to the design

2. Lower thermal efficiencies

3. Poorer environmental compliance, primarily due to low cost, compact size, and quick deliveries

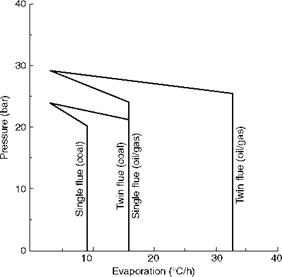

Fire tube boilers of smaller size are vertical and those of larger size are horizontal. Figure 1.1 depicts their range. The minimum capacity of a water tube boiler is usually around 5 tph.

Combo boilers are generally used for solid fuel firing in lower ranges of up to 30 tph for lower pressures <25 atm. Fire tube and combo boilers are not discussed in this book.

• Industrial boilers

• Utility boilers

• Marine boilers

•

|

FIGURE 1.1 Range of smoke or flue tube shell boilers. |

![]() Nuclear boilers

Nuclear boilers

|

|

Only the industrial and power utility boilers are discussed here and in Chapters 9 through 14.

• Mass/pile burning boilers

• Stoker-fired boilers

• Burner-fired boilers

• Bubbling fluidized bed combustion (BFBC) boilers

• Circulating fluidized bed combustion (CFBC) boilers

• Pulverized fuel (PF) boilers

• Liquor-fired boilers

• Waste heat boilers

Most of these boilers are further classified as follows:

• Stoker-fired boilers are categorized as chain grate, dump grate, spreader stoker, and reciprocating grate.

• Bubbling fluidized bed combustion boilers are grouped as underbed and overbed.

• Circulating fluidized bed combustion boilers are classified as hot cyclone, cold cyclone, U-beam, and compact designs.

• Pulverized fuel boilers are categorized as wall-fired and corner-fired boilers.

• Waste heat boilers are separated as process waste heat recovery boilers (WHRBs) and boilers behind heat recovery steam generators (HRSGs); only the latter are discussed in this book. HRSGs are classified into vertical and horizontal designs.

Most of these boilers are described in Chapters 9 through 14.

• Subcritical boilers

• Supercritical (SC) boilers

With —200 bar serving as the dividing line. These are discussed in detail in Chapter 9.

• Natural circulation or drum-type boilers

• Forced circulation boilers

• Once-through (OT) or no-drum boilers

• Natural or balanced draft boilers

• Forced draft (FD) or pressurized fired boilers

Boilers can be further classified based on construction features.

• Package boilers

• Field-erected boilers

• Top-supported boilers

• Bottom-supported boilers

• Middle — and girdle-supported boilers

• Two-pass boilers

• One and a half-pass boilers

• Single or tower-type boilers

• Down-shot boilers

Range and Diversity of Boilers

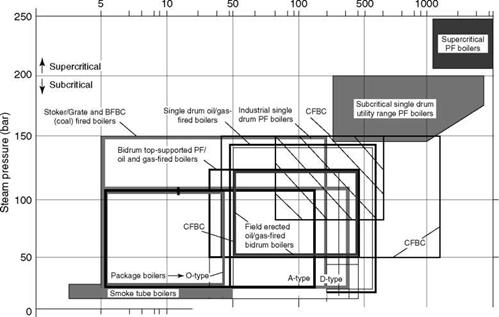

Boilers are made in various shapes and sizes to burn a variety of fuels with the end purpose of producing varying amounts of steam for either process or power or both. An attempt is made here to capture practically the whole range of fired boilers, from the humble smoke/flue tube boilers for modest steam to the ultra-supercritical (USC) for megapower plants in a single graph to let the reader get acquainted with the magnitude and variety. Figure 1.2 helps to provide an insight into the diversity. It is to be noted that

|

|

|

Generator output (MW) |

|

175 350 500 700 1500 J__ ,__ I_ ,_ I_ ,_ L____ I____ |

|

75 150 |

|

250 1 450 1 |

|

5000 — 250 |

|

— 200 |

|

— 150 |

|

100 |

|

50 |

|

10 |

|

N—- 1—n—- 1——- 1—m——- 1—— 1—n—I——— 1—m——— 1— 1—r 50 100 500 1000 5000 |

|

Boiler capacity (tph) |

|

(Note: log scale) |

|

FIGURE 1.2 Range of steam generators along with approximate electric power equivalents. |

|

35 |

|

800 1000 |

|

5 |

The boiler capacity is on a log graph, which helps at once to accommodate the entire range, but also renders a visual distortion.

20 июля, 2013

20 июля, 2013  admin

admin

Опубликовано в рубрике

Опубликовано в рубрике