There are four main inputs and four outputs for any conventional boiler, excluding the RH. The terminal points (TPs) in these circuits define the end points of the scope of supply, with all equipment between the TPs within the scope of boiler suppliers. Table 1.1 the classical

|

TABLE 1.1 Boiler Inputs and Outputs

|

|

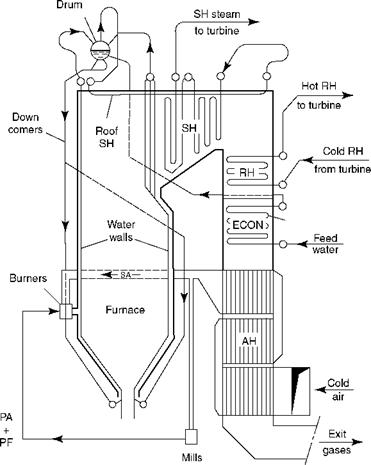

FIGURE 1.3 Drum-type RH utility boiler with ECON and AH as back-end equipment. |

Scope and TPs shows a typical large conventional boiler in a power or a cogen plant, which is depicted in Figure 1.3.

In a water and steam circuit, the boiler scope starts at the nonreturn valve (NRV) at the ECON or the drum inlet (if there is no ECON) and ends at the main steam stop valve (MSSV) or NRV (if provided). In case of variable-pressure boilers, where there is no MSSV, the scope ends at the turbine inlet valve.

|

TABLE 1.2 Heat Recovery Steam Generator Inputs and Outputs

|

In an air and gas circuit, the scope begins at the inlet flanges of the FD fan. Also it starts at the suction flanges of PA and SA fans where the suction is from the atmosphere. The scope ends at the discharge of the induced draft (ID) fan at a suitable point, but usually at the stack inlet.

In a fuel circuit, the scope starts at the inlet flange of the feeder for solid fuels or at the fuel main stop valve for liquid and gaseous fuels. The scope ends at the ash hoppers.

The isolating valves on the chemical dosing lines on the feed and drums determine the limits. The drain and blow-off lines and continuous blowdown lines terminating in the dirty and clean blowdown vessels, respectively, are included along with the tanks and their escape pipes.

Dust-collecting equipment may or may not form a part of the scope. Deaerators and feed stations are also not included as they are in the turbine island. The TPs for a typical HRSG are somewhat different, as shown in Table 1.2.

24 июля, 2013

24 июля, 2013  admin

admin

Опубликовано в рубрике

Опубликовано в рубрике