The purpose of raising steam in a boiler in a power plant is to expand it in a turbine to derive mechanical energy from heat energy (and with the help of a generator convert it into electrical power). The fully expanded steam (to vacuum levels) is converted back into water by cooling and condensing the vapor in a condenser and returning to the feed pump to pressurize the subcooled water to the required boiler pressure. This cycle is called the steam or Rankine cycle; the salient features of which are as follows:

• Heat from the condenser is wasted and it pays to minimize this loss.

• Cycle efficiency = (total heat of steam — heat loss in condenser)/total heat of steam

= area under 1234561/area under 12345 in Figure 2.1.

|

100 |

RH |

|

|

75 — |

||

|

50 |

||

|

Evaporator |

Critical |

|

|

25- |

Pressure |

|

|

0 |

Economizer |

|

A Њ I |

|

100 |

|

150 200 Pressure (bar) |

FIGURE 2.3

Workload of heating surfaces as the pressure increases.

|

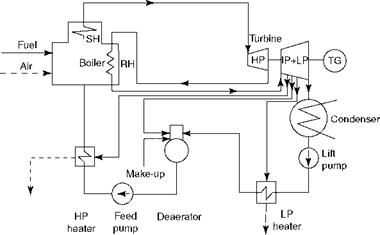

FIGURE 2.4 Simplified schematic of a steam cycle in a power plant. |

• In the total heat of steam, the heat to RH is also included if an RH is installed. The cycle efficiency improves with the RH as the heat to steam increases more than the loss from condenser.

• The cycle efficiency increases when

— The steam is generated at the highest possible pressure and temperature.

— The condenser vacuum is the lowest possible.

— The condenser vacuum is limited by the cooling water inlet temperature and the permissible temperature rise.

• Cycle efficiency can be further improved by regenerative heating of the condensate, by extracting some part of steam from the turbine and transferring its heat to the condensate, instead of expanding to the condenser pressure fully and losing all the latent heat to the cooling water. This is done progressively over several pressure levels in the turbine to transfer the optimum energy to increase the efficiency.

Figure 2.4 shows a simplified steam cycle with two-stage regenerative feed heating.

8 августа, 2013

8 августа, 2013  admin

admin

Опубликовано в рубрике

Опубликовано в рубрике