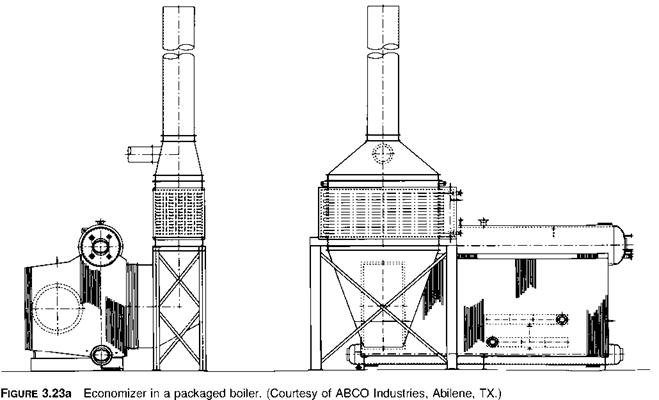

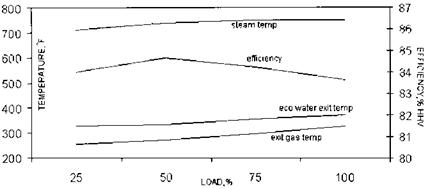

Plant engineers are interested in knowing how a given boiler performs at various loads. The variables affecting its performance are the fuel, amount of excess air, FGR rate, and steam parameters. Tables 3.4 And 3.7 Show how boiler performance varies with load on gas and oil firing. Figure 3.24 Shows the results in graph form. The following observations can be made:

1. As the load increases, the boiler exit gas temperature increases. This is due to the larger flue gas mass flow transferring energy to a given heating surface. The water temperature leaving the economizer is higher at loads owing to the higher gas temperature entering the economizer. The approach point (difference between saturation and water temperature entering evaporator) is lower at higher loads. Steaming in the economizer is not a concern in steam generators because the approach point is quite large at full load and increases at lower loads. The ratio of gas flow to steam generation is maintained at 1.2-1.3 at various loads. Hence the economizer does not absorb more energy at low loads as in the case of HRSGs.

2. The boiler efficiency increases as the load increases, peaks at about 5070% of load, then drops off. The two major variables affecting the heat losses are the casing heat losses and heat loss due to flue gases. Q6.24 discusses this calculation. As the load increases, the flue gas heat losses

|

|

|

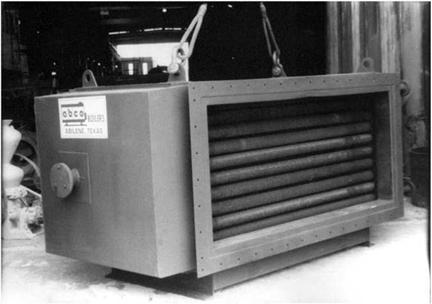

Figure 3.23b Photo of an economizer. (Courtesy of ABCO Industries, Abilene, TX.) |

Increase due to the higher exit gas temperature. The casing loss decreases as a percentage but, as explained in Q6.24, in terms of Btu/h it remains the same because the evaporator operates at saturation temperature, so heat losses in Btu/h are unaffected by boiler load except if ambient temperature or wind velocity changes. Thus the combination of these losses results in a parabolic shape for efficiency as a function of load.

3. The steam temperature generally increases with load owing to the convective nature of the superheater. If a radiant design were used, it would decrease slightly at higher loads.

4. It may also be seen that the gas temperature leaving the evaporator decreases as the load decreases. If an SCR is used between the evaporator and the economizer, the gas temperature should be maintained in the range of typically 650-780°F; hence one may have to use a gas bypass system to obtain a higher gas temperature at low loads. Chapter 4 shows the arrangement of dampers to achieve this purpose.

5. The steam temperature on oil firing is lower than that in gas firing. This is due to the better absorption of energy from the oil flames in the

TABLE 3.7 Boiler Performance—Oil Firing

Load (%)

|

25 |

![]() 50 75 100

50 75 100

|

Boiler duty, MM Btu/h |

28.94 |

|

Excess air, % |

30 |

|

Fuel input, MM Btu/h |

32.98 |

|

Heat rel rate, Btu/ft3 h |

15,266 |

|

Heat rel rate, Btu/ft2 h |

28,188 |

|

Steam flow, lb/h |

25,000 |

|

Steam temp, °F |

694 |

|

Economizer exit water |

324 |

|

Temp, °F |

|

|

Boiler exit gas temp, °F |

526 |

|

Economizer exit gas |

254 |

|

Temp, °F |

|

|

Air flow, lb/h |

32,064 |

|

Flue gas, lb/h |

33,731 |

|

Dry gas loss, % |

3.95 |

|

Air moisture loss, % |

0.1 |

|

Fuel moisture loss, % |

6.58 |

|

Casing loss, % |

1.2 |

|

Margin, % |

0.5 |

|

Efficiency, % HHV |

87.67 |

|

Efficiency, % LHV |

93.67 |

|

Furnace back pressure, |

0.8 |

|

In. WC |

|

58.26 |

89.03 |

118.71 |

|

15 |

15 |

15 |

|

65.95 |

101.25 |

135.9 |

|

30,531 |

46,875 |

62,918 |

|

56,376 |

86,554 |

116,176 |

|

50,000 |

75,000 |

100,000 |

|

710 |

750 |

750 |

|

329 |

350 |

368 |

|

588 |

671 |

748 |

|

269 |

296 |

325 |

|

56,728 |

87,096 |

116,903 |

|

60,061 |

92,212 |

123,771 |

|

3.83 |

4.36 |

4.95 |

|

0.1 |

0.11 |

0.13 |

|

6.62 |

6.69 |

6.77 |

|

0.6 |

0.4 |

0.3 |

|

0.5 |

0.5 |

0.5 |

|

88.35 |

87.93 |

87.35 |

|

94.39 |

93.95 |

93.33 |

|

2.45 |

5.81 |

10.76 |

Steam pressure = 500psig, oil firing. HHV = 19,727; LHV = 18,463 Btu/lb. Flue gas analysis (vol%): CO2 = 10.76, H2O = 11.57, N2 = 73.63, O2 = 2.51.

|

Figure 3.24 Boiler performance versus load. |

Furnace, which results in a lower furnace exit gas temperature and lower gas temperature at the superheater in oil firing. Hence the steam temperature is lower. However, if we wanted to maintain the same steam temperature on both oil and gas firing, we would have to size the superheater so that it makes the steam temperature in the oil-firing case and then control it in gas firing by attemperation.

30 июля, 2013

30 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике