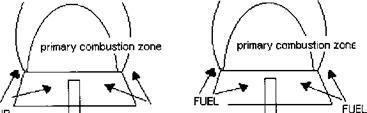

Staged combustion is widely used by burner suppliers to reduce NOx. In this method, the fuel or air is added in increments (Fig. 4.12) so that at no point in the flame is an exceptionally high temperature obtained. In air staging, a fuel-rich mixture is initially created, followed by the addition of air at the burner tip to burn the remaining fuel. As little as 60% of the total combustion air is introduced into the primary combustion zone. The substoichiometric operation generates a high level of partial pressures of hydrogen and CO, and these reducing agents limit the NOx formation. The second-stage air is introduced downstream to complete the combustion process after some heat has been transferred to the process, thereby limiting the formation of thermal NOx. The staging of air does provide some control over both thermal and fuel NOx.

|

Secondary combustion zone |

![]()

|

Airv |

![]()

|

AIR |

![]()

|

FUEL |

![]()

|

Figure 4.12 Staging of fuel and air in burners. |

![]()

|

AIR FUEL STAGING |

![]()

|

AIR STAGING |

![]() A concept that is a little more effective for reducing thermal NOx is fuel staging. Staged fuel burners are widely used. A portion of the fuel and all of the combustion air are introduced into the primary combustion zone. Rapid combus-

A concept that is a little more effective for reducing thermal NOx is fuel staging. Staged fuel burners are widely used. A portion of the fuel and all of the combustion air are introduced into the primary combustion zone. Rapid combus-

|

Secondary combustion zone |

Tion is achieved in the fuel-rich atmosphere with a high level of excess air, which reduces the peak flame temperature, thereby reducing thermal NOx. The fuel for the second stage is introduced through a series of nozzles positioned around the burner perimeter. This fuel is introduced in such a manner that the final combustion occurs after heat has been transferred to the process, lowering the final combustion temperature. In addition, the secondary fuel is injected at a relatively high pressure, which, because of the position of the secondary tips, entrains flue gases; this simulates flue gas recirculation, which helps lower the combustion temperature. Although fuel staging helps lower thermal NOx by up to 75%, it does not reduce the amount of fuel NOx generated. However, this is a small portion of the overall NOx in gas-fired boilers. Fuel staging is difficult with liquid fuels. Fuel staging also helps operation at lower excess air than air staging. A few burner suppliers are able to promise less than 30ppmvd NOx using this technique.

7 августа, 2013

7 августа, 2013  doctype

doctype  Опубликовано в рубрике

Опубликовано в рубрике