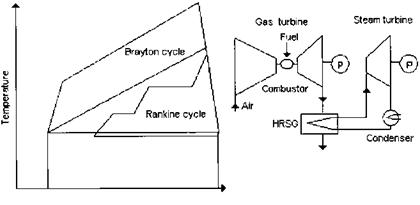

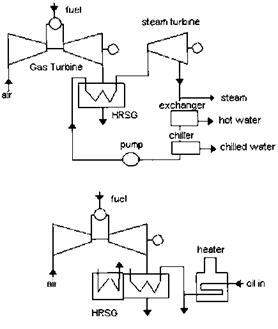

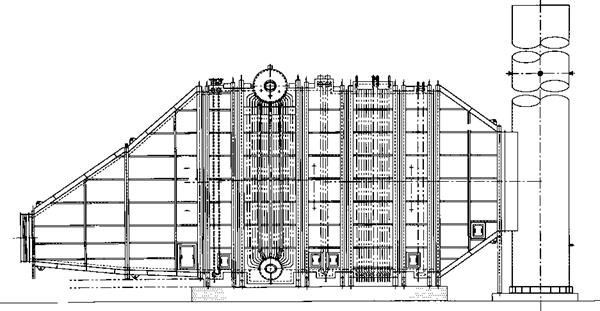

Gas turbine plants operate in both combined cycle and cogeneration mode (Fig. 1.9). Figure 1.10 Shows the arrangement of an unfired HRSG used in such plants. Large combined cycle plants with thousands of megawatts in capacity are being built today. Chemical plants, refineries, and process plants use HRSGs in cogeneration mode to supply steam for various purposes. The combined cycle plant with a gas turbine exhausting into an HRSG that supplies steam to a steam turbine is the most efficient electric generating system available today. It exhibits lower capital costs than fossil power plants. Table 1.1 Shows the average cost of a gas turbine. The HRSG price ranges from about $80 to $130 per kilowatt. Combining the Brayton and Rankine cycles results in efficiencies significantly above the 40% level, which was an upper limit of large coal-fired utility plants built 30-50 years ago. Distillate oils and natural gas are typically fired in the gas turbines. Combined cycle plants have a number of advantages:

Modular designs enable increases in plant capacity as time passes.

These plants have short start-up periods. They come on-line in a couple of hours from the cold.

Combined cycle plants can be built within 12-20 months, unlike a large utility plant, which takes 3-4 years.

|

Entropy Figure 1.9a Combined cycle system showing the Brayton—Rankine cycle. |

|

To Distillation unit Figure 1.9b Cogeneration systems. |

Advances in gas turbine technology and cooling systems can be made use of to improve the overall system efficiency. We are close to 60% LHV efficiency with recent developments such as high pressure, multiple- pressure steam systems and reheat steam cycles.

Emissions of NOx and CO for plants burning natural gas are in single-digit plants per million (ppm).

Cooling water requirements are low due to higher efficiency and the small ratio of Rankine cycle power to total power output. The Brayton cycle portion does not require cooling water.

Large-capacity additions are feasible. Today’s combined cycle plant is rated in thousands of megawatts, which is otherwise feasible only with coal — fired power plants.

Recent developments in gas turbine technology such as closed steam cooling of blades enable firing temperatures to be increased, thus increasing the simple cycle efficiency. Every 100°F increase in firing temperature increases the turbine power output by 10% and gives a 4% gain in simple cycle efficiency. In large systems, an HRSG with three pressure levels and reheat is used,

|

|

|

Figure 1.10 Unfired HRSG in a gas turbine plant. |

|

TABLE 1.1 Gas Turbine Pricing

Note: A host of factors affect pricing, and the above numbers give an idea only and should be used with caution. Source: Ref. 14. |

Increasing the plant efficiency to 55% LHV Table 1.2 Presents data for a few systems that are being commercially offered. The data are typical only.

In spite of all the advantages mentioned, it should be noted that the output of a gas turbine decreases significantly as the ambient temperature increases. The lower density of warm air reduces the mass flow through the turbine and the exhaust gas flow through the HRSG, which in turn reduces its steam generation and hence the steam turbine power output. Unfortunately, hot weather also corresponds to peak electrical loads in many areas of the world. Hence a few methods are used to improve the gas turbine power output in summer. The three most common methods of increasing the gas turbine (GT) output are [7]

Injection of steam into the gas turbine Precooling of the inlet air Supplementary firing in the HRSG

10 июля, 2013

10 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике