Diesel engines are widely used as sources of power when an electrical utility supply is not available. They may be fired on gaseous or liquid fuels. They are mostly employed in low and medium power cogeneration units, typically 50 kW to 10 MW for natural gas firing, 50 kW to 50 MW for diesel, and 2.5-50 MW for heavy fuel oils. They are widely used in countries where the electricity supply is not reliable. Diesel plants have several advantages and features:

Medium-sized reciprocating engines have substantially higher electrical efficiencies than gas turbines of similar size (34-40% vs. 25-30%). Partial load efficiencies are also higher.

They require lower fuel gas pressure for operation—20-40 psig compared to 180-400 psig for gas turbines.

Electrical power output is less sensitive to ambient air temperature. The output of a gas turbine drops off at higher ambient temperatures as discussed above.

Capital costs are higher than these for gas turbines by 10-25%. Operating and maintenance costs are also higher, but diesel engines can be used on heavy fuel oils, so fuel costs are lower. Developing countries use diesel engine sets for on-site power needs because the power supply is not dependable in many locations.

In applications calling for high power to heat recovery, hot water or low — pressure steam, reciprocating engines are preferred to gas turbines. A lower exhaust gas temperature (650-800°F) makes them less suitable for high pressure heat recovery systems than gas turbines; also, the exhaust gas contains less oxygen, on the order of 10-12% compared to 14-15% for turbine exhaust, making supplementary firing difficult, though not impossible.

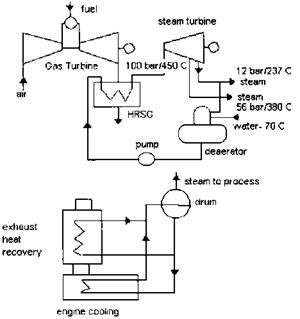

There are two main sources of heat available in diesel engines. One is the engine cooling water, and the other is the exhaust gas (Fig. 1.21). The exhaust gas temperature is often below 750°F, hence only low pressure saturated or superheated steam is generated. Depending on the cleanliness of the gas stream, water tube boilers with extended surfaces could be used for heat recovery, though bare tube boilers with soot blower provisions are often used. Fire tube boilers are used if the gas flow is small, less than 50,000 lb/h. In many plants several diesel engines are used at the same time; hence by combining the exhaust gas flow into a single large duct, a single waste heat boiler could be built. The gas is often pulsating, so the boiler and casing design has to be rugged. Work is also being done to supplementary fire the diesel engine exhaust by using solid fuels to generate high pressure steam for combined cycle operation.

|

Figure 1.21 Diesel engine heat recovery system. Top: Combined cycle plant. Bottom: Diesel cogeneration. |

17 июля, 2013

17 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике