Generally gas turbines perform poorly at low loads, which affect not only their [11, 12] performance but also that of the HRSG located behind them. Because of the low exit gas temperature at lower loads, the HRSG generates less steam and also has the potential for steaming in the economizer. Table 1.4 Shows the exhaust flow and temperature of a small gas turbine as a function of load. It should be noted that the data are typical, presented to illustrate the point that at low gas

|

Table 1.3 Gas Turbine Performance at Selected Ambient Temperatures

|

|

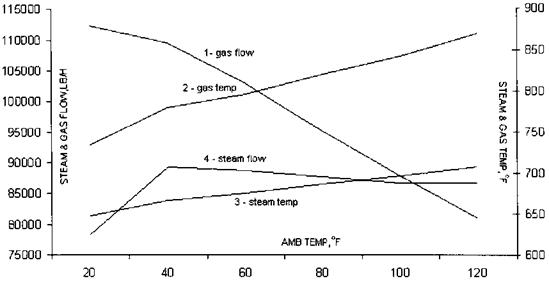

FIgure 1.11 HRSG performance versus ambient temperature. Gas flow shown has a multiplication factor of 0.1. |

Table 1.4 Typical Gas Turbine Performance at Low Loads

|

Load (%) |

||||

|

10 |

20 |

30 |

40 |

100 |

|

Generator kW |

415 |

830 |

1244 |

1659 |

4147 |

|

Heat rate, Btu/kWh |

48,605 |

28,595 |

21,960 |

18,649 |

12,882 |

|

Efficiency, % |

7 |

12 |

15.54 |

18.3 |

26.5 |

|

Exhaust gas, Ib/h |

147,960 |

148,068 |

148,170 |

148,320 |

148,768 |

|

Exhaust temp, °F |

562 |

612 |

662 |

712 |

1019 |

|

VoI% CO2 |

1.18 |

1.38 |

1.59 |

1.79 |

3.04 |

|

H2O |

3.76 |

4.14 |

4.53 |

4.93 |

7.33 |

|

O2 |

18.18 |

17.78 |

17.28 |

16.88 |

14.13 |

|

N2 |

76.9 |

76.7 |

76.6 |

76.4 |

75.5 |

Turbine loads the HRSG performance will be poor. Note that at low loads the exhaust temperature is lower but the mass flow changes little.

The HRSG performance at 100% and 40% loads is given iN Figs. 1.12a And 1.12b. The HRSG was designed for the 100% case, and its performance was checked at 40% load using the ‘‘HRSGS’’ program. It may be seen that the economizer generates some steam. Also, the exit gas temperature from the HRSG at low load is very high compared to the normal case. This is due to the fact that less steam is generated in the evaporator and hence the flow through the economizer is also small, resulting in only a small gas temperature drop; the heat sink at the economizer is not large enough to cool the gases to a low temperature. Thus it is recommended that the HRSG not be operated at low loads of the gas turbine for long durations. If it is absolutely required, then a gas bypass damper should be used, or methods suggested in Q8.41, may be tried to minimize economizer steaming.

12 июля, 2013

12 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике