Fouling is a serious concern in both fire tube and water tube boilers, particularly with dirty gas streams. It affects not only the waste heat boiler performance but

|

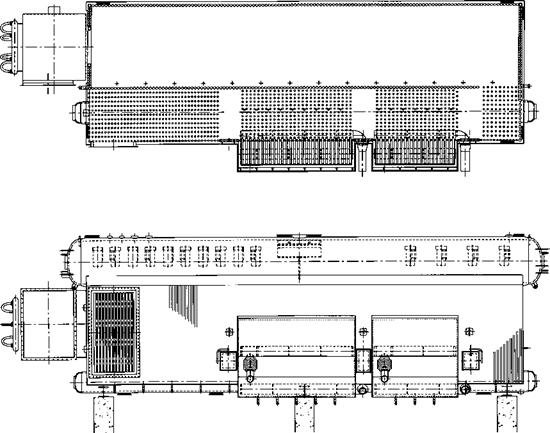

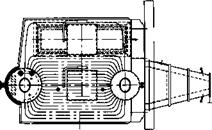

FIgure 2.14 D-type waste heat boiler for operation with burner and waste heat. (Courtesy of ABCO Industries, Abilene, TX.) |

|

|

|

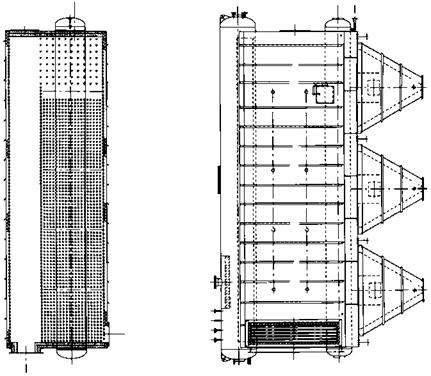

FIgure 2.15 Waste heat boiler in carbon black plant. (Courtesy of ABCO Industries, Abilene, TX.) |

Also equipment such as scrubbers downstream of the boiler. When fouling sets in, the steam generation decreases and the gas pressure drop increases over a period of time. There are a few ways to infer if the fouling has become severe:

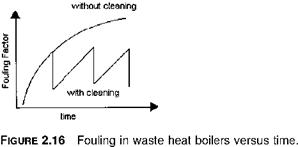

1. The exit gas temperature from the boiler will increase over a period of time; if, say, the normal exit gas temperature from the convection bank is 550°F and we observe 570-600°F for the same load, then we can infer that fouling has set in. Fouling deposits build up over heat transfer surfaces (whether inside or outside), and the fouling factor increases exponentially and then tapers off as shown in Fig. 2.16. With periodic cleaning some of the deposits are removed, which decreases the fouling factor, but a base layer builds up and increases the exit gas temperature and decreases the boiler duty. A complete shutdown and cleaning may help restore the original boiler performance or close to it.

2. The gas pressure drop across the convection section increases. If the fan power consumption increases over a period of time, then one can infer that there is some blockage of the gas path and that fouling has set in.

3. Steam generation naturally decreases with fouling.

4. Superheated steam temperature, if a superheater is present, has to be looked at carefully, because fouling in different sections may be different, and one cannot conclude that there is fouling at a given surface without having data on the gas inlet and exit temperatures and steam inlet and exit temperatures and flows. Sometimes steam-side fouling is caused by deposition of salts from steam. Steam-side fouling can increase the tube wall temperatures and cause overheating as discussed in Q8.13. Steam-side fouling is more critical in finned water tube boilers, as discussed in Q8.24.

One has to shut down the boiler and perform an investigation if fouling is severe. Normal fouling may be acceptable between maintenance shutdowns. Heat transfer calculations backed up with field data and tube wall temperature

|

|

Measurements can also show if the fouling is on the gas side or steam side or both. With gas-side fouling the tube wall temperatures will not increase, whereas with steam-side fouling the tube wall temperatures can increase significantly. With a combination of gas — and steam-side fouling, the measurement of operating data on each side, followed by elaborate calculations, can reveal the extent of fouling.

Because both fire tube and water tube boilers are used in HRSGs, a few guidelines on their sizing are in order.

21 июля, 2013

21 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике