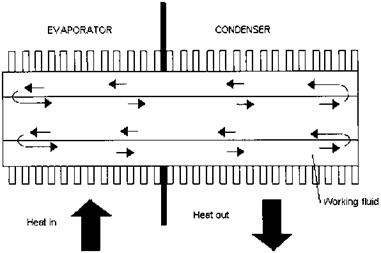

Heat pipes (Fig. 3.28) were introduced into the heat recovery market about 40 years ago. A heat pipe consists of a bundle of pipes filled with a working fluid such as toluene, naphthalene, or water and sealed. Heat from the flue gas evaporates the working fluid collected in the lower end of the slightly inclined pipes (6-10° from horizontal), and the vapor flows to the condensing section, where it gives up heat to the incoming combustion air.

Condensed fluid returns by gravity to the evaporative section assisted by an internal capillary wick, which is essentially a porous surfaces or circumferentially spiraled grove of proprietary design. The process of evaporation and condensa-

|

Figure 3.28 Arrangement of a heat pipe. |

Tion continues as long as there is a temperature difference between the air and flue gases.

In a typical design, there is a divider plate at the middle of the tube that supports the tube and also maintains a seal between the hot flue gases and the cold air. Pipe surfaces are finned to make the heat transfer surfaces compact. Finned surfaces are used because the heat transfer coefficient inside the tubes is very high due to the condensation and evaporation. Fin density is based on cleanliness of the gas stream.

Heat pipes offer several advantages over conventional air heaters:

1. They are compact and weigh less than other air heaters due to the use of extended surfaces.

2. They have zero leakage because the pipes are stationary and the divider plate is welded to the tubes.

3. No auxiliary power is needed, because heat pipes do not need a power source to operate.

4. Maintenance is low because there are no rotating parts.

5. They have low corrosion potential. Owing to the isothermal behavior of the pipes, the minimum tube metal temperature is higher than in other types of exchangers. By selecting proper working fluids, it is possible to maintain the cold end above the acid dew point. The tubes also operate at constant temperature along their entire length because of the phase transfer process.

6. They undergo only low stresses because the tubes are fixed at the midpoint and are allowed to expand at either end.

7. Individual pipe failure does not appreciably affect the overall performance of the unit.

8. Gas — and air-side pressure drops are generally lower than in tubular or regenerative air heaters owing to the compactness of the design.

2 августа, 2013

2 августа, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике