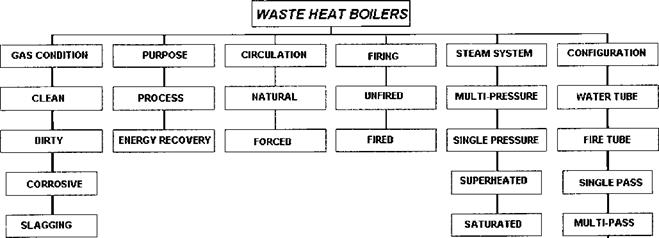

Heat recovery boilers, also known as waste heat recovery boilers or heat recovery steam generators (HRSGs), form an inevitable part of chemical plants, refineries, power plants, and process systems. They are classified in several ways, as can be seen in Fig. 2.1, according to the application, the type of boiler used, whether the flue gas is used for process or mainly for energy recovery, cleanliness of the gas, and boiler configuration, to mention a few. The main classification is based on whether the boiler is used for process purposes or for energy recovery. Process waste heat boilers are used to cool waste gas streams from a given inlet temperature to a desired exit temperature for further processing purposes. An example can be found in the chemical industry in a sulfuric acid or hydrogen plant where the gas stream is cooled to a particular gas temperature and then taken to a reactor for further processing. The exit gas temperature from the boiler is an important parameter affecting the downstream process reactions and hence is controlled by using a gas bypass system. Steam generation is of secondary importance in such plants. In energy recovery applications, on the other hand, the gas is cooled as much as possible while avoiding low temperature corrosion. Examples can be found in gas turbine exhaust heat recovery or flue gas heat

|

|

|

ELEVATED DRUM |

![]()

|

COMBINATION |

![]() Figure 2.1 Classification of waste heat boilers.

Figure 2.1 Classification of waste heat boilers.

Recovery from incinerators, furnaces, and kilns. The objective here is to maximize energy recovery.

If the gas stream is clean, water tube boilers with extended surfaces may be used. In solid or liquid waste incineration applications, the gas is generally dirty and may contain corrosive compounds, acid vapors, ash, and particulates. If the ash contains compounds of sodium, potassium, or nonferrous metals, slagging is likely on heat transfer surfaces if these compounds become molten. In these cases, bare tube boilers with provision for cleaning the tubes with soot blowers or a rapping mechanism are used. A water-cooled furnace, which cools the gas stream to a temperature below the ash melting temperature and hence minimizes slagging on the convective surfaces, may also be necessary.

Generally if the gas inlet temperature is high, say above 1400°F, a singlepressure heat recovery system is adequate to cool the gases to about 300-350°F. In gas turbine exhaust heat recovery applications with a low inlet gas temperature to the HRSG of 900-1000°F, a single-pressure heat recovery system cannot cool the gases adequately and a multipressure steam system is often required.

In the United States HRSGs are generally of natural circulation design, whereas in Europe it is very common to see once-through and forced circulation designs. The features of these boilers are discussed later.

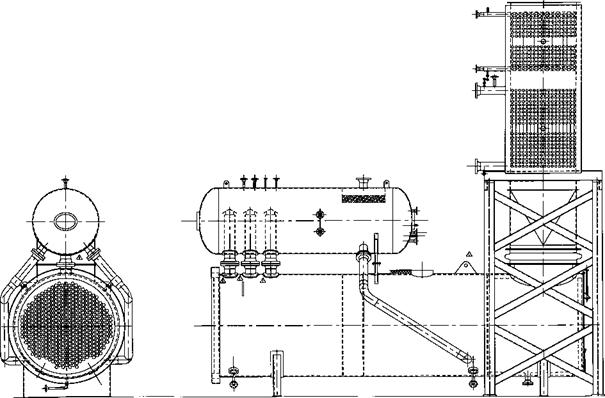

Flue gas analysis is important to the design of the boiler. A large amount of water vapor or hydrogen increases the specific heat and thermal conductivity of the gas and hence the boiler duty and heat flux. For example, the reformed gas in hydrogen plants has a large volume of hydrogen and water vapor, which increases the heat transfer coefficient by 500-800% compared to typical flue gases. Hence heat flux is of concern in these types of boilers. Hydrogen chloride (HCl) vapor in the flue gases indicates corrosive potential, particularly if a superheater operating at high metal temperatures, say exceeding 900°F, is present. The presence of sulfur trioxide (SO3) vapor and HCl also suggests low temperature corrosion problems due to their low acid dew points. Flue gas pressure in waste heat boilers is typically atmospheric or a few inches of water column (in. WC) above or below atmospheric pressure; however, there are applications such as the use of a reformed gas boiler or synthesis gas boiler in hydrogen or ammonia plants where the gas pressure could be as high as 300-1500 psig (see Chap. 8, Table 8.46). Fire tube boilers are generally preferred for these applications, though special water tube boiler designed with heat transfer surfaces located inside pressure vessels have been built.

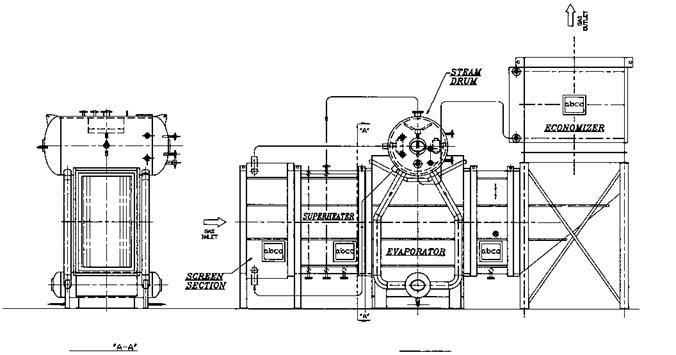

A common classification of boilers is based on whether the gas flows inside or outside the tubes. In fire tube boilers, the flue gases flow inside the tubes (Fig. 2.2), whereas in water tube boilers, the gas flows outside the tubes as shown in Fig. 2.3. The features of each type are discussed in the following section.

|

FIgure 2.2 Fire tube waste heat boiler with superheater and economizer. (Courtesy of ABCO Industries, Abilene, TX.) |

|

Figure 2.3 Water tube waste heat boiler with superheater and economizer. (Courtesy of ABCO Industries, Abilene, TX. |

18 июля, 2013

18 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике