Basic human needs can be met only through industrial growth, which depends to a great extent on energy supply. The large increase in population during the last few decades and the spurt in industrial growth have placed tremendous burden on the electrical utility industry and process plants producing chemicals, fertilizers, petrochemicals, and other essential commodities, resulting in the need for additional capacity in the areas of power and steam generation throughout the world. Steam is used in nearly every industry, and it is well known that steam generators and heat recovery boilers are vital to power and process plants. It is no wonder that with rising fuel and energy costs engineers in these fields are working on innovative methods to generate electricity, improve energy utilization in these plants, recover energy efficiently from various waste gas sources, and simultaneously minimize the impact these processes have on environmental pollution and the emission of harmful gases to the atmosphere. This chapter briefly addresses the status of various power generation systems and the role played by steam generators and heat recovery equipment.

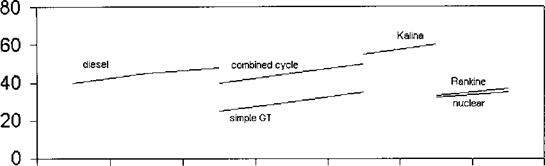

Several technologies are available for power generation such as gas turbine based combined cycles, nuclear power, wind energy, tidal waves, and fuel cells, to mention a few. Figure 1.1 Shows the efficiency of a few types of power systems.

1 5 10 50 100 500 1000

Figure 1.1 Efficiency of typical power systems.

About 40% of the world’s power is, however, generated by using boilers fired with pulverized coal and steam turbines operating on the Rankine cycle. Large pulverized coal fired and circulating fluidized bed supercritical pressure units are being considered as candidates for power plant capacity addition, though several issues such as solid particle erosion, metallurgy of pressure parts, maintenance costs, and start-up concerns remain. It may be noted that in Europe and Japan supercritical units are more widespread than in the United States.

In spite of escalation in natural gas prices, gas turbine capacity has increased by leaps and bounds during the last decade. Today’s combined cycle plants are rated in thousands of megawatts, unlike similar plants decades ago when 100MW was considered a very high rating. Steam pressure and temperature ratings for heat recovery steam generators (HRSGs) in combined cycle plants have also increased, from 1000 psig a decade or so ago to about 2400psig. Reheaters, which improve the Rankine cycle efficiency and are generally used in utility boilers, are also finding a place in HRSGs. Complex multipressure, multimodule HRSGs are being engineered and built to maximize energy recovery.

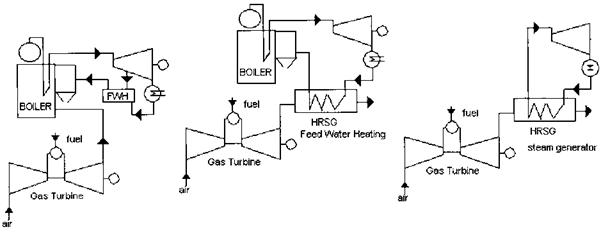

Repowering existing steam power plants typically 30 years or older with modern gas turbines brings new useful life in addition to offering a few advantages such as improved efficiency and lower emissions. A few variations of this concept are shown in Fig. 1.2. In boiler repowering, the gas turbine exhaust is used as combustion air for the boiler. Owing to the size of such plants, solid fuel firing may be feasible and perhaps economical. Another option is to increase the power output of the steam turbine by not using the extraction steam for feedwater heating, which is performed by the turbine exhaust gases in the HRSG. The exhaust gases can also generate steam with parameters in the HRSG similar to these of the original coal-fired boiler plant, which can be taken out of service. Because gas turbines typically use premium fuels, the emissions of NOx, CO2, and SOx are also reduced in these repowering projects. It may be noted that the various HRSG options discussed above are challenging to design and build, because numerous parameters are site-specific and cost factors vary from case to case.

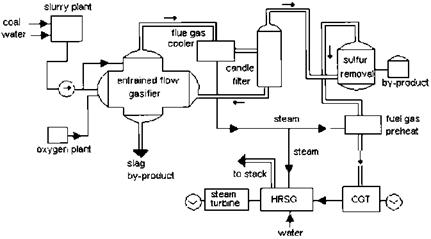

Significant advances have been made in research and development of alternative methods of coal utilization such as fluidized bed combustion and gasification; integrated coal gasification and combined cycle (IGCC) plants are not research projects any longer. A few commercial plants are in operation throughout the world. Figure 1.3 Shows a typical plant layout.

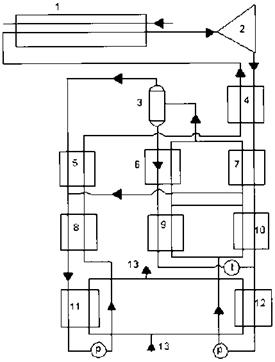

Research into working fluids for power generation have also led to new concepts and efficient power generation systems such as the Kalina cycle (Fig.

1.4) , which uses a mixture of ammonia and water as the working fluid in Rankine cycle mode. The use of organic vapor cycles in low temperature energy recovery

|

Figure 1.2 Repowering concepts to salvage aging power plants. |

|

FIgure 1.3 Wabash integrated coal gasification and combined cycle plant. |

Applications is also widespread. Gas turbine technology is being continuously improved to develop advanced cycles such as the intercooled aero derivative (ICAD), humid air turbine (HAT), and Cheng cycle. We have come a long way from the 35% efficiency level of the Rankine cycle to the 60% level in combined cycle plants.

Heat sources in industrial processes can be at very high temperatures, 1000-2500°F, or very low, on the order of 250-500°F, and applications have been developed to recover as much energy from these effluents as possible in order to improve the overall energy utilization. Heat recovery steam generators form an important part of these systems. (Note: The terms waste heat boiler, heat recovery boiler, and heat recovery steam generator are used synonymously). Waste gas streams sometimes heat industrial heat transfer fluids, but in nearly 90% of the applications steam is generated, that is used for either process or power generation via steam turbines.

Condensing heat exchangers are used in boilers and in HRSGs when economically viable to recover a significant amount of energy from flue gases that are often below the acid and water dew points. The condensing water removes acid vapors present in the gas stream along with particulates if any. In certain process plants, energy recovery and pollution control go hand in hand for economic and environmental reasons. Though expensive, condensing economizers, in addition to improving the efficiency of the plant, help conserve water, a precious commodity in some areas. See Chapter 3 for a discussion on condensing exchangers.

|

FIgure 1.4 Kalina cycle scheme at Canoga Park, CA. 1, HRVG; 2, turbine; 3, flash tank; 4, final preheater; 5, HP preheater; 6, second recuperator; 7, vaporizer; 8, HP preheater; 9, first recuperator; 10, LP preheater; 11, HP condenser; 12, LP condenser; 13, cooling water; t, throttling device; p, pump. |

Today if we walk into any chemical plant, refinery, cogeneration plant, combined cycle plant, or conventional power plant, we can see the ubiquitous steam generators and heat recovery boilers, because steam is needed virtually everywhere for process and power generation. Boiler and HRSG designs are being continuously improved to meet the challenges of higher efficiency and lower emissions and to handle special requirements if any. For example, one of the requirements for auxiliary boilers in large combined cycle plants is quick start-up; packaged boilers generating saturated or superheated steam are required to come up from hot standby condition to 100% capacity in a few minutes if the gas turbine trips. Packaged boilers with completely water-cooled furnaces (Fig.

1.5) are better suited for this application than refractory-lined boilers. In addition to generating power or steam efficiently, today’s plants must also meet strict

|

FIgure 1.5 Packaged steam generator with completely water-cooled furnace. (Courtesy of ABCO Industries, Abilene, TX.) |

Environmental regulations relating to emissions of NOx, SOx, CO, and CO2, which adds to the complexity of their designs.

9 июля, 2013

9 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике