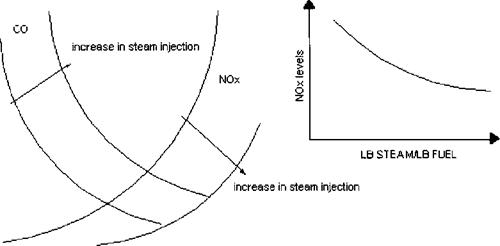

Boiler and burner suppliers sometimes use steam injection to reduce the flame temperature and thus decrease NOx. Steam generators as well as gas turbines use this method. In boilers the steam consumption could vary by 1-3% of the total steam generated, thus reducing the boiler output; however, the significant reduction in NOx may offset the need for FGR or other methods. The NOx reduction is more significant with gas firing than with oil firing. A side effect of water or steam injection is the increase in CO content. Hence there should be a compromise between the efforts to reduce NOx and CO.

|

FIRING TEMPERATURE Figure 4.11 Effect of steam-water injection on NOx and CO. |

In HRSGs, steam or water injection in to the gas turbine combustor is used along with catalysts located in the HRSG to limit NOx to single digits. The increase in water vapor content on SCR performance has to be reviewed. Steam injection also increases the gas turbine power output due to the increased mass flow and higher specific heat of the gases with increased water vapor content. This concept is used in the Cheng cycle power system discussed in Chapter 1.

Water or steam injected into gas turbines has to be treated to give high steam purity. Steam purity should be preferably in the parts per billion range. The treated water is lost to the atmosphere and has to be evaluated as an operating cost in such systems.

7 августа, 2013

7 августа, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике