The superheater is an important component of a packaged boiler. The degree of superheat could be very high, with steam temperatures up to 1000°F, or as low as 50°F. With a very low degree of superheat, one can locate the superheater behind the evaporator and ahead of the economizer. In this case, the superheater may require a large surface area due to the low log-mean temperature difference, but extended surfaces may be used (if distillate oils and gaseous fuels are fired) to make it compact.

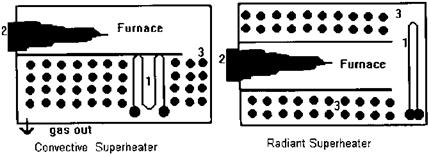

Radiant superheaters, which are typically located in the furnace exit region, are widely used by several boiler manufacturers. Radiant superheaters have to be designed very carefully because they operate in a much harsher environment than convective superheaters, which are located in the convective zone behind screen tubes as shown in Fig. 3.17a. Radiant superheaters are located at the furnace exit or in the turning section (Fig. 3.17b). The furnace exit gas temperature is a difficult parameter to estimate. Variations in excess air, flue gas recirculation rates, and burner flame patterns can affect this value and the temperature distribution across the furnace exit plane. The gas temperature in operation could be off by 100-150°F from the predicted value. The turning section is also subject to nonuniformity in gas flow and turbulence, which can affect the superheater performance. Thus its duty can be either underestimated or overestimated by a large margin.

The convective superheater is shielded behind screen tubes as shown in Fig. 3.17a and often operates at 1800-1900°F in comparison with the 2200-2300°F for radiant designs. Because it operates at lower tube wall temperatures, its life can be longer, but it requires a greater surface area because of the lower log-mean temperature difference. However, owing to the lower operating temperatures, a convective superheater can use a lower grade material than the radiant design, and this helps balance the cost to some extent. Also, its location behind screen tubes helps reduce the gas flow nonuniformity to a great extent; hence predicting its performance is easier and more reliable than predicting the performance of the single-stage radiant superheater.

|

Figure 3.17 Location of convective and radiant superheater. 1, Superheater; 2, burner; 3, screen evaporator. |

Several boilers operate at partial loads of less than 60% for large periods. The radiant superheater, by its nature, absorbs more enthalpy at lower loads, hence the steam temperature increases at lower loads. Convective heat transfer depends on mass flow of flue gases, so as the load decreases, the gas flow and temperature decrease at the superheater region, and therefore the steam temperature and the tube wall temperatures drop with load. Also if at 100% load the steam-side pressure drop in a radiant superheater is 50 psi, then at 30%, it will be about 5 psi, which can lead to concerns about steam flow distribution through the tubes when it is receiving more radiant energy per unit mass of steam. Coupled with nonuniform gas flow distribution at low loads and low gas velocities, the radiant superheater poses several concerns about its tube wall temperatures and hence its life.

The convective superheater is located behind several rows of screen tubes that shield it from furnace radiation. Gas flow entering the superheater is well mixed; hence it is easier to predict its performance and tube wall temperatures. As mentioned earlier, its surface area requirement may be more, but one is assured of low tube wall temperatures and hence longer life.

The steam temperature in a convective superheater generally decreases as the load falls off, whereas in a radiant design it remains within a small range over a larger load range. Hence the convective design has to be sized to ensure that the required steam temperature is achieved at the lowest load, which can increase its size and cost.

The choice of whether to use a radiant or a convective superheater is based on the experience of the supplier. Because the surface area requirements are significantly different due to the different log-mean temperature differences, this is yet another reason that a comparison of surface areas can be misleading.

If heavy oil is fired in the boiler, the problems associated with slagging and high temperature corrosion pose concerns for the longevity and operability of radiant superheaters as discussed below, so convective superheater designs are preferred in such cases. Packaged boilers use limited space compared to utility or field-erected boilers; with high gas velocities and slagging potential in the furnace exit region, the radiant design is vulnerable. Even with a convective superheater design, care should be taken to use retractable soot blowers, and there should be adequate space provided for cleaning and maintenance.

29 июля, 2013

29 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике