Like any other equipment, a boiler has to be configured and operated at the optimum efficiency—a function of the fuel and interest costs. As the fuel costs have increased, the boilers have also improved in their efficiency. In gas-rich countries, for example, GTs still operate on open cycle with no HRSGs to recover the heat. The payback period to install the HRSGs is too long to be economical.

The most important of all the boiler parameters is the efficiency calculation. The process is extremely simple with just about six steps. But the essence of the boiler design with all refinements is captured in those few steps. Each defining parameter has to be carefully evaluated to ensure that it can indeed be translated into reality in a working boiler. For example, the excess air level should be acceptable to the firing equipment and the infiltration should be realistic. The final exit gas temperatures must be economically feasible and cause no corrosion. The efficiency calculation is the first and the last calculation for any boiler, as the committed efficiency figure has to be finally demonstrated in the field.

|

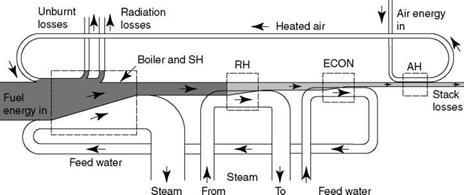

Energy HP turbine LP turbine energy in FIGURE 1.4 Energy balance in a boiler plant. (From Power Magazine. With permission.) |

|

TABLE 1.3 Heat Inputs, Outputs, and Loss

|

This is practically the only calculation that the customer and consultant should be interested in receiving from a boilermaker. This proposal stage calculation has to be validated with the performance stage calculation at startup, proving the claim a year or two later. It is to be noted that although the result is the same, there is a difference in the design and field calculations because the inputs are different at both stages. This will be evident in the next few paragraphs.

Efficiency on gross calorific value (GCV) or net calorific value (NCV)? Boiler efficiency is measured on the basis of GCV or NCV, both capturing different aspects of operation. Also refer to Section 3.2.1.1.3. The former, popular in the United States and the countries following the American systems, indicates how much of the total fuel heat is converted into the heat in steam whereas the latter, popular in Europe and the countries following the European systems, indicates how much of the available heat of fuel is converted into the heat in steam.

Net calorific value is the practically available heat of fuel included in total heat (GCV) arrived at after discounting the heat carried away by water vapor (inherent in fuel and produced by the burning of H2 in fuel), assuming the vapor pressure to be —0.07 atm or 1 psia. Accordingly, the NCV works out as

NCV = GCV — 1040 (m + 9H2) Btu/lb or GCV — 578 (m + 9H2)kcal/kg (1.2)

Where 1040 Btu/lb or 578 kcal/kg is the latent heat of evaporation. This figure varies slightly with the testing code adopted; 1055 Btu/lb or 586 kcal/kg is another figure used. But the difference is very small.

A biofuel such as bagasse gives an efficiency as low as 68% on GCV due to its very high moisture, whereas its equivalent on the basis of NCV is as high as 90%. From NCV it is clear that the boiler is highly efficient having reclaimed such a high percentage of available heat, whereas the modest 68% gives a misleading picture. But the efficiency of GCV determines how much fuel is needed to make the required steam. The difference, however, is not so large with prime fuels. With coal, typically, the difference is —4%, for example, 88 and 92% on GCV and NCV with PF firing, respectively. Both concepts are efficient.

Two processes are at work, namely

• Heat release from fuel in the firing equipment

• Heat absorption in the heating surfaces of the heat released

How well the two processes are performed determines the efficiency. Add to it a couple of inevitable systemic losses such as radiation loss (Lr) from the boiler’s enclosure and sensible heat loss of the ash and the picture is complete. Efficiency of a boiler is always measured with ambient conditions as the datum and the atmosphere as the sink. The ambient conditions have a significant effect on the efficiency and the design.

27 июля, 2013

27 июля, 2013  admin

admin

Опубликовано в рубрике

Опубликовано в рубрике