It is generally believed that combined cycle plant efficiencies with fired HRSGs are lower than those with unfired HRSGs. The reason is not the poor performance of the HRSG. In fact, a fired HRSG by itself is efficient. However, the large losses associated with the Rankine cycle, particularly when the steam turbine power is a large fraction of the overall power output, distorts the results slightly as the following example shows.

|

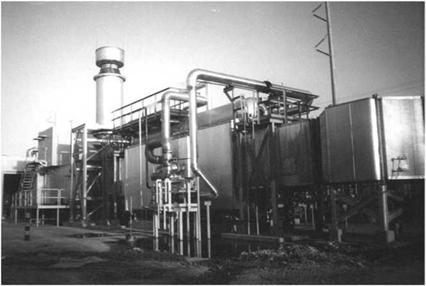

Figure 1.14b Photograph of a furnace-fired ABCO HRSG in a cogeneration plant. |

|

Table 1.6 General Features of Fired and Unfired HRSGs

|

A combined cycle plant uses a fired HRSG. The gas turbine used is LM 5000. At 59°F,

Exhaust gas flow= 1,030,000 lb/h at 800°F.

Gas analysis, vol%: CO2 = 2.8, H2O = 8.5, N2 = 74.4, O2 = 14.3 Power output =35 MW; heat rate = 9649 Btu/kWh Steam turbine data:

Inlet pressure = 650 psia at 750°F Exhaust pressure = 1 psia

Efficiency = 80%, dropping off by 2-3% at 40% load.

HRSG data:

230°F feedwater, 2% blowdown, 1% heat loss Steam is generated at 665psia and 750°F.

The HRSG generates 84,400 lb/h in the unfired mode and a maximum of 186,500 lb/h when fired up to 1200°F. The HRSG performance was simulated by using the HRSGS program. The system efficiency in both cogeneration and combined cycle mode are calculated as follows:

Gas turbine fuel input = 35,000 x 9649 = 337.71 MM Btu/h, lower heating value (LHV) basis.

Cogeneration mode efficiency at 900°F, from first principles (or fundamentals) =

(35 X 3.413 + 129.9) x 100 = 67.9%

337.71+29.6

Where 129.9 MM Btu/h is the HRSG output and 29.6MM Btu/h is the HRSG burner input in LHV (lower heating value basis).

Combined cycle mode efficiency:

(35 + 12.1) x 3.413 V ’ ^nr x 100 = 43.8%

337.71+29.6

Where 12.1 MW is the power output from the steam turbine.

Table 1.7 Shows the results at various HRSG firing temperatures. Cogeneration plant efficiency improves with firing in the HRSG as discussed earlier. The combined cycle plant efficiency drops only because of the lower efficiency of the Rankine system as the proportion of power from the Rankine cycle increases. The HRSG, as can be seen, is efficient in the fired mode with a slightly lower stack gas temperature.

|

Table 1.7 Cogeneration and Combined Cycle Efficiency with Fired HRSG

|

|

ABoiler duty is the energy absorbed by steam, MM Btu/h. bBurner duty is the fuel input to HRSG, MM Btu/h, LHV basis. |

13 июля, 2013

13 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике