Today’s cogeneration plants have both HRSGs and packaged steam generators. To generate a desired quantity of steam efficiently, the load vs. efficiency characteristics of both the HRSG and steam generator should be known. Although the generation of steam with the least fuel input is the objective, it may not always be feasible, for reasons of plant loading, availability or maintenance, However the information is helpful for planning purposes [13].

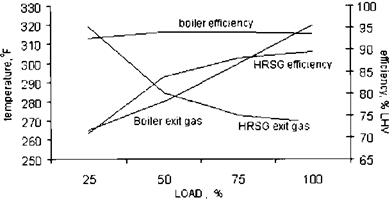

To explain the concept, an HRSG and a packaged boiler both capable of generating up to 100,000 lb/h of 400psig saturated steam on natural gas are considered. In order to understand how the cogeneration system performs, one should know how the HRSG and the steam generator perform as a function of load. Figure 1.15 Shows the load vs. efficiency characteristics of both the HRSG and packaged boiler. The following points may be noted.

1. The exit gas temperature from the HRSG decreases as the steam

Generation is increased. This is due to the fact that the gas flow remains the same while the steam flow increases, thus providing a larger heat sink at the economizer as discussed earlier. On the other hand, the exit gas temperature from the steam generator increases as the load increases because a larger quantity of flue gas is handled by a given heat transfer surface.

2. The ASME HRSG efficiency increases as firing increases as explained

In Q8.38. The range between the lowest and highest load is significant. The steam generator efficiency increases slightly with load, peaks around 60-75%, and drops off. The variation between 25% and 100%

Loads is marginal. This is due to the combination of exit gas losses and

Casing heat losses. The casing loss is nearly unchanged with load in Btu/h but increases as a percentage of total loss at lower loads. The

|

FIgure 1.15 Load versus efficiency characteristics of HRSG and steam generator. |

Flue gas heat loss is lower at lower loads due to the lower exit gas temperature and mass flow.

Performance calculations were done at loads ranging from 25% to 100% for both the steam generator and the HRSG. Results are presented in Tables 1.8 and

Table 1.8 Steam Generator Performance at Various Loadsa

Load (%)

25 50 75 100

Steam flow, Ib/h Excess air, %

Duty, MM Btu/h Flue gas, lb/h Exit gas temp, °F Dry gas loss, %

Air moisture, %

Fuel moisture, % Casing loss, % Efficiency, HHV % Efficiency, LHV % Fuel, MM Btu/h (LHV)

|

25,000 |

50,000 |

|

30 |

10 |

|

25.4 |

50.8 |

|

30,140 |

50,600 |

|

265 |

280 |

|

3.93 |

3.56 |

|

0.1 |

0.09 |

|

10.43 |

10.49 |

|

2.00 |

1.0 |

|

83.54 |

84.86 |

|

92.58 |

94.05 |

|

27.5 |

54.0 |

|

75,000 |

100,000 |

|

10 |

10 |

|

76.3 |

101.6 |

|

76,150 |

101,750 |

|

300 |

320 |

|

3.91 |

4.27 |

|

0.1 |

0.11 |

|

10.58 |

10.66 |

|

0.7 |

0.5 |

|

84.7 |

84.46 |

|

93.87 |

93.60 |

|

81.3 |

108.6 |

ASteam pressure = 400 psig; feedwater = 230°F, blowdown = 5%. Fuel: natural gas. C = 97, C2 = 2, C3 = 1 vol%

Table 1.9 HRSG Performance at Various Loads3

|

Load |

||

|

25 |

50 75 |

100 |

|

Steam generation, lb/h |

25,000 |

50,000 |

75,000 |

100,000 |

|

Duty, MM Btu/h |

25.4 |

50.8 |

76.3 |

101.6 |

|

Exhaust gas flow, lb/h |

152,000 |

153,140 |

154,330 |

155,570 |

|

Exit gas temp ° F |

319 |

285 |

273 |

269 |

|

Fuel fired, MM Btu/h (L) |

0 |

24.5 |

50.0 |

76.5 |

|

ASME efficiency, % |

70.8 |

83.79 |

88.0 |

89.53 |

|

ASteam pressure = 400 psig; feedwater = 230°F; 5% blowdown. Fuel input is on LHV basis. |

1.9. Additional performance calculations may also be done for intermediate steam generation values. Table 1.10 presents the total fuel required for a given total steam output and shows the split between the boiler and HRSG steam generation.

It is obvious that the HRSG should be used first to make any additional steam, because its fuel utilization is the best. However, if for some reason we cannot operate the HRSG, then information on how the total fuel consumption varies with the loading of each type of boiler helps in planning. For example, if

100,0 lb/h of steam is required, the steam generator can be shut off completely and the HRSG can be fully fired; the next best mode is to run the HRSG at

|

Table 1.10 Fuel Consumption at Various Loads

|

75,0 lb/h and the boiler at 25,000 lb/h or in that range. A similar table may be prepared if there are multiple units in the plant, and by studying the various combinations a plan for efficient fuel utilization can be developed. Note that a typical packaged boiler generates steam at about 92% efficiency on LHV basis, whereas it is nearly 100% if the same amount of fuel (gas or oil) is fired in an HRSG.

13 июля, 2013

13 июля, 2013  doctype

doctype

Опубликовано в рубрике

Опубликовано в рубрике