8.1 Estimating surface area of heat transfer equipment; overall heat trans

Fer coefficient; approximating overall heat transfer coefficient in water tube boilers, fire tube boilers, and air heaters; log-mean temperature difference

8.2 Estimating tube-side heat transfer coefficient; simplified expression for

Estimating tube-side coefficient

8.3 Estimating tube-side coefficient for air, flue gas, water, and steam

8.4 Estimating heat transfer coefficient outside tubes

8.5 Estimating convective heat transfer coefficient outside tubes using

Grimson’s correlations

8.6 Effect of in-line vs. staggered arrangement

8.07a Evaluating nonluminous radiation heat transfer using Hottel’s charts

8.07b Nonluminous radiation using equations

8.08a Predicting heat transfer in boiler furnaces

8.08b Design of radiant section for heat recovery application

8.09a Evaluating distribution of radiation to tube banks

8.09b Estimating the temperature of a lance inside boiler enclosure

8.11 Effect of gas velocity, tube size on fire tube boiler size

8.12 Computing heat flux, tube wall temperatures

8.13 Effect of scale formation on tube wall temperature and boiler perforMance

8.14 Design of water tube boilers

8.15a Predicting off-design performance

8.15b Logic for off-design performance evaluation for water tube boilers

8.16 Estimating metal temperature in a boiler superheater tube; thermal resistances in heat transfer; calculating heat flux

8.17 Predicting performance of fire tube and water tube boilers

8.18 Why finned tubes are used and their design aspects

8.19a Heat transfer and pressure drop in finned tubes using ESCOA correla

Tions

8.19b Heat transfer in finned tubes using Briggs and Young correlation

8.19c Predicting the performance of a finned tube superheater

8.20 Sizing of finned tube evaporator

8.21 Comparison of bare tube and finned tube boilers

8.22 In-line versus staggered arrangement

8.23 Effect of tube-side heat transfer on fin configuration

8.24 Effect of tube-side fouling on bare and finned tube boilers

8.25 Estimating weight of finned tubes

8.26 Effect of fin thickness and conductivity on boiler performance and tube and fin tip temperatures

8.27a Is surface area an important criterion for boiler selection?

8.27b Optimization of a finned evaporator surface

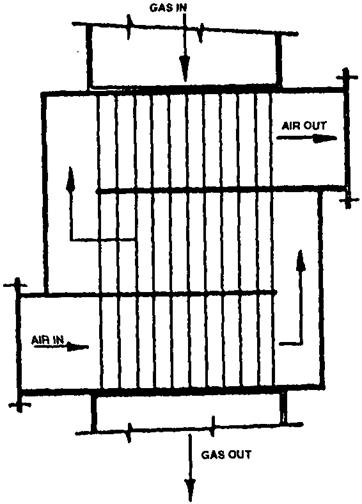

8.28 Design of tubular air heaters

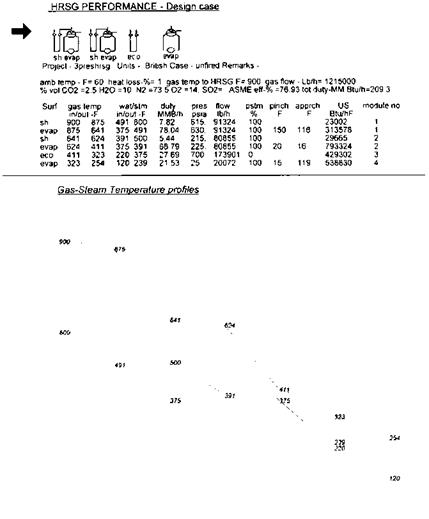

8.29 Off-design performance of air heaters

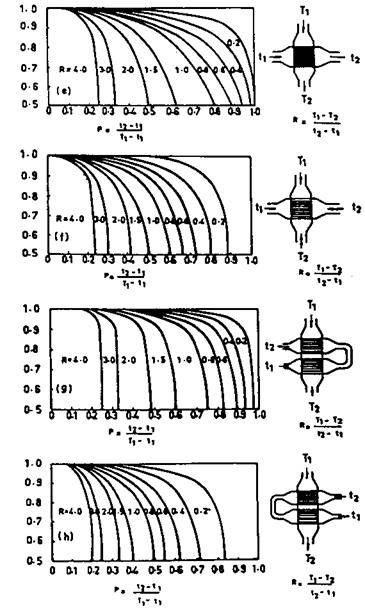

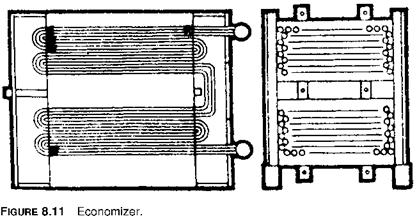

8.30 Predicting performance of economizers using NTU method

8.31 Evaluating natural convection heat transfer coefficients in air

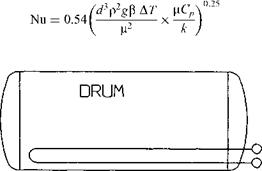

8.32 Natural convection heat transfer in liquids

8.33 Determining size of coil/tube bundle immersed in liquids

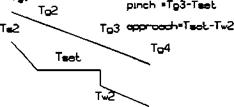

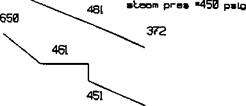

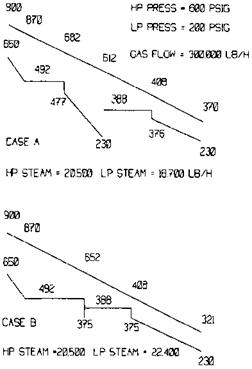

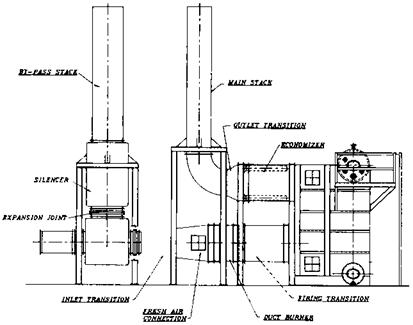

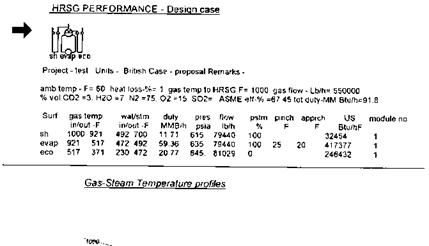

8.34 Evaluating gas/steam temperature profiles in HRSGs

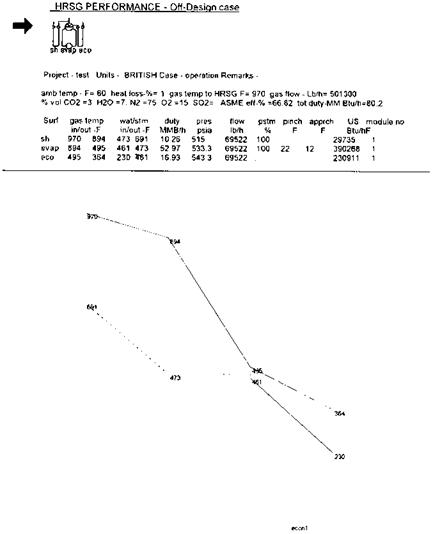

8.35a Simulating off-design performance

8.35b A simplified approach to determining auxiliary fuel requirement in an

HRSG

8.36 Why gas exit temperature cannot be assumed in HRSGs

8.37 How to optimize temperature profiles in HRSGs

8.38 Efficiency of HRSGs according to ASME Power Test Code

8.39a Effect of fresh air fan size on HRSG performance

8.39b Performance of a multipressure HRSG in fresh air-fired mode

8.40 How to evaluate operating costs in HRSGs

8.41 Why economizer steaming occurs in gas turbine HRSGs

8.42 Why water tube boilers are preferred to fire tube boilers for gas turbine applications

8.43 Why 10% increase in surface area does not mean 10% more duty in boilers or heat transfer equipment

8.44a Time required to heat up boilers

8.44b Transient heating of a superheater bundle

8.44c Transient response of a water tube evaporator to cutoff in heat input and

Feedwater supply

8.44d Response of a water tube evaporator when steam demand increases and feedwater supply is cut off 8.45a Parameters to be considered in testing performance of HRSGs

8.45b Evaluating HRSG performance from operating data

8.46 Estimating boiling heat transfer coefficient and critical heat flux in water

Tube boilers

8.47a Relating heat flux, steam pressure, quality, flow in water tube boilers

8.47b Estimating critical heat flux in fire tube boilers

8.47c Estimating critical heat flux in a fire tube boiler; correcting for bundle

Geometry

8.48 Simplified approach to designing fire tube boilers

8.49 Simplified approach to designing water tube boilers

8.50 Estimating tube bundle size

8.51 Estimating thickness of insulation for flat and curved surfaces; effect of

Wind velocity; estimating thickness to limit surface temperatures

8.52 Estimating surface temperature of given thickness of insulation; trial- and-error procedure to determine casing temperature

8.53 Sizing insulation to prevent freezing; determining water dew point

8.54a Estimating heat loss from pipes for various insulation thicknesses

8.54b Estimating temperature drop of fluids in insulated piping

8.55 Optimum thickness of insulation; life-cycle costing; annual heat loss and capitalized cost; annual heat loss if no insulation is used

8.56 Design of hot casing

8.57 Temperature of duct or stack wall with and without insulation

8.58 Effect of wind velocity, casing emissivity on heat loss

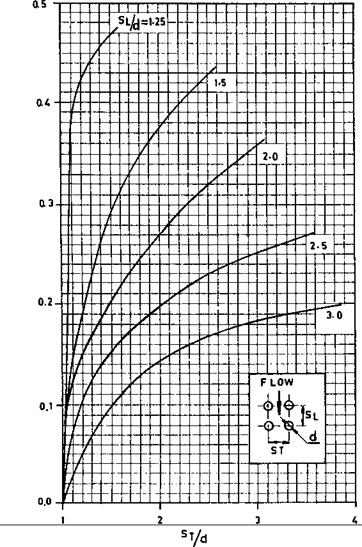

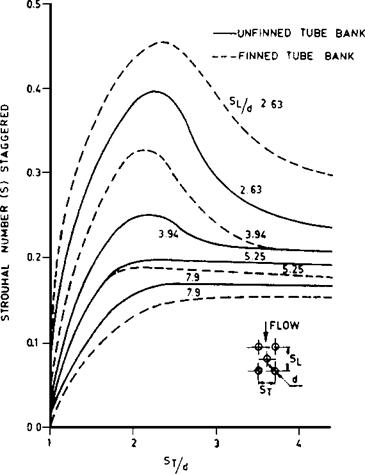

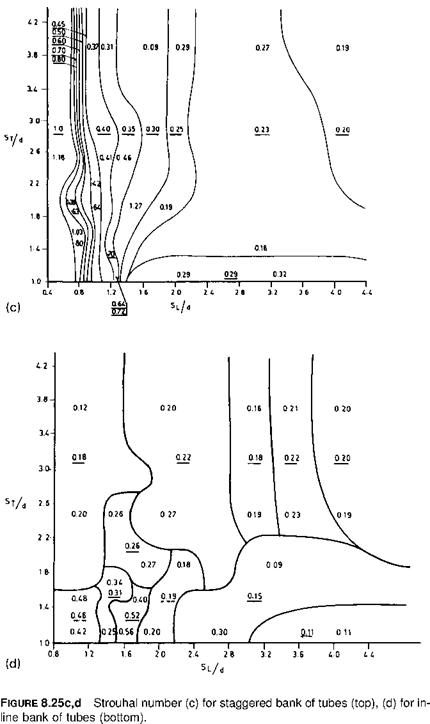

8.59a Checking for noise and vibration problems in heat transfer equipment

8.59b Determining natural frequency of vibration of a tube bundle

8.59c Computing acoustic frequency

8.59d Determining vortex shedding frequency

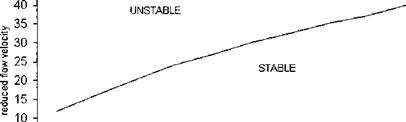

8.59e Checking for bundle vibrations

8.59f Checks for tube bundle vibration using damping and fluid elastic instability criteria

8.60 Estimating specific heat, viscosity, and thermal conductivity for a gas mixture

8.61 Effect of gas analysis on heat transfer

8.62 Effect of gas pressure on heat transfer

8.63 Converting gas analysis from weight to volume basis

8.64 Effect of gas pressure and analysis on design of fire tube boiler

How is the surface area of heat transfer equipment determined? What terms can be neglected while evaluating the overall heat transfer coefficient in boilers, economizers, and superheaters?

The energy transferred in heat transfer equipment, Q, is given by the basic equation

Q = U x A x A T (1)

Also,

Wh Ahh = Wc Ahc (2)

Where

A = surface area, ft2 W = fluid flow, lb/h

Ah = change in enthalpy (subscripts h and c stand for hot and cold)

AT = corrected log-mean temperature difference, °F U = overall heat transfer coefficient, Btu/ft2h °F

For extended surfaces, U can be obtained from [1] 1 A A

U = h~At + ff ‘■x A + ff o+

At d, d 1

— x——- x In — H——

Aw 24Km dt zh0

Where

At = surface area of finned tube, ft2/ft A,- = tube inner surface area = %di/12, ft2/ft Aw = average wall surface area = p(d + d,)/24, ft2/ft Km = thermal conductivity of the tube wall, Btu/fth °F

D, d, = tube outer and inner diameter, in. ff,, ffo = fouling factors inside and outside the tubes, ft2h °F/Btu h,, ho = tube-side and gas-side coefficients, Btu/ft2h °F Z = fin effectiveness

If bare tubes are used instead of finned tubes, At = pd/12.

Equation (3) can be simplified to

1 d 1 d d

U = hd + ho+ 24k; x d

D (4)

+ ff, x d + ffo

Where ho is the outside coefficient.

Now let us take the various cases.

Water Tube Boilers, Economizers, and Superheaters

The gas-side heat transfer coefficient ho is significant; the other terms can be neglected. In a typical bare tube economizer, for example, h, = 1500 Btu/ft2 h °F, ff, and ffo = 0.001 ft2h °F/Btu, and ho = 12 Btu/ft2 h °F. d = 2.0 in., d, = 1.5 in., and Km = 25 Btu/fth °F.

Substituting into Eq. (4) yields

1 2.0 1 2.0 , 2

— ——————— 1—- 1———— x ln —

U 1500 x 1.5 12 24 x 25 1.5

+ 0.001 x 20 + 0.001 = 0.0874

Hence,

U = 11.44 Btu/ft2 h °F

Thus we see that the overall coefficient is close to the gas-side coefficient, which is the highest thermal resistance. The metal thermal resistance and the tube-side resistance are not high enough to change the resistance distribution much.

However, in a liquid-to-liquid heat exchanger, all the resistances will be of the same order, and hence none of the resistances can be neglected.

TOC o "1-5" h z Even if finned tubes were used in the case above, with At/A, = 9 substituted into Eq. (3), U = 9.3 Btu/ft2 h °F, which is close to ho. Thus, while trying to

Figure U for economizers, water tube boilers, or gas-to-liquid heat exchangers, U

May be written as

U = 0.8 to 0.9 x ho (5)

Ho is large, on the order of 1000-1500Btu/ft2h°F, whereas h, will be about 10- 12Btu/ft2h °F. Again, using Eq. (4), it can be shown that

U h x d (6)

All the other thermal resistances can be seen to be very small, and U approaches the tube-side coefficient h,.

Gas-to-Gas Heat Exchangers (Example: Air Heater in Boiler Plant)

In gas-to-gas heat transfer equipment, both hi and ho are small and comparable, while the other coefficients are high.

Assuming that ho = 10 and hi = 15, and using the tube configuration above,

1

|

-4 |

![]() 2.0 1

2.0 1

+ —- + 0.001 + 9.6 x 10

U 15 x 1.5 10

+ 0.001 x 15 = 0.1922

Or

U = 5.2 Btu/ft2 h °F

Simplifying Eq. (4), neglecting the metal resistance term and fouling, we obtain

H:d:/d , ,

U=hox hoiim (7)

Thus both ho and h, contribute to U.

AT, the corrected log-mean temperature difference, can be estimated from

AT — AT —

AT = FT x —ATmm_

Ln(ATmax/ATmin)

Where FT is the correction factor for flow arrangement. For counterflow cases, FT = 1.0. For other types of flow, textbooks may be referred to for FT. It varies from 0.6 to 0.95 [2]. ATmax and ATmin are the maximum and minimum terminal differences.

In a heat exchanger the hotter fluid enters at 1000°F and leaves at 400°F, while the colder fluid enters at 250°F and leaves at 450°F. Assuming counterflow, we have

ATmax = 1000 — 450 = 550°F ATmin = 400 — 250 = 150°F

Then

550 — 150

AT = mc55i07T50) = 307°F

How is the tube-side heat transfer coefficient ht estimated?

The widely used expression for ht is [1]

TOC o "1-5" h z Nu = 0.023 Re0 8 Pr0 4 (8)

Where the Nusselt number is

Nu = пЙ (9)

The Reynolds number is

Wd, , ,

Re = 15.2—, (10)

Where w is the flow in the tube in lb/h, and the Prandtl number is

Pr=mi (ii)

where

M = viscosity, lb/fth Cp = specific heat, Btu/lb °F k = thermal conductivity, Btu/fth °F

All estimated at the fluid bulk temperature.

Substituting Eqs. (9)-(11) into Eq. (8) and simplifying, we have

W°-8k°-6CS’4 w°-8C

Hi = 2’44 x d/V4 = 2’44 x "dp" (12)

Where C is a factor given by

|

-‘p |

![]() K 0’6c0’4

K 0’6c0’4

|

M0’4 |

![]() C = ■

C = ■

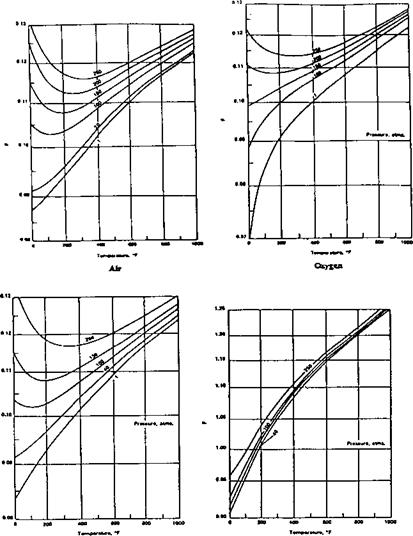

C is available in the form of charts for various fluids [1] as a function of temperature. For air and flue gases, C may be taken from Table 8.1.

For hot water flowing inside tubes, Eq. (8) has been simplified and, for t < 300°F, can be written as [3]

V08

H, — = (150 + 1.550-^ (13)

Where

V = velocity, ft/s t = water temperature, °F

For very viscous fluids, Eq. (8) has to be corrected by the term involving viscosities at tube wall temperature and at bulk temperature [1].

Estimate h, when 200 lb/h of air at 800°F and atmospheric pressure flows in a tube of inner diameter 1.75 in.

|

Table 8.1 Factor C for Air and Flue Gases

|

Using Table 8.1 And Eq. (12), we have C = 0.187.

0 187

H = 2.44 x 2000 8 x ‘ ia = 11.55 Btu/f2 h °F ‘ 1.7518

Where

W = flow, lb/h

Dt = inner diameter, in.

For gases at high pressures, Ref. 1 gives the C values. (See also p. 531.)

In an economizer, 50,000 lb/h of water at an average temperature of 250°F flows in a pipe of inner diameter 2.9in. Estimate ht.

Let us use Eq. (13). First the velocity has to be calculated. From Q5.07a,

V = 0.05(wv/dt2). v, the specific volume of hot water at 250°F, is 0.017 cuft/lb. Then, t

|

V = 0.05 x 50,000 x -2-^ = 5.05 ft/s |

![]() 0.017

0.017

J00 x

Hence, from Eq. (13),

5 05°’8

H- = (150 + 1.55 x 250) x —= 1586 Btu/ft2 h °F

2’90’2

Estimate the heat transfer coefficient when 4000lb/h of superheated steam at 500psia and an average temperature of 750°F flows inside a tube of inner diameter 1.5in.

Using Table 8.2, we see that C = 0.318. From Eq (12)

Ht = 2.44 x 4000—X80 318 = 285 Btu/ft2 h °F 1.518

If steam were saturated, C = 0.383 and ht = 343 Btu/ft2 h°F.

|

Pressure (psia)

|

How is the outside gas heat transfer coefficient ho in boilers, air heaters, economizers, and superheaters determined?

The outside gas heat transfer coefficient ho is the sum of the convective heat transfer coefficient hc and nonluminous heat transfer coefficient.

Ho = hc + (14)

For finned tubes, ho should be corrected for fin effectiveness. is usually small

If the gas temperature is less than 800°F and can be neglected.

A conservative estimate of hc for flow of fluids over bare tubes in in-line and staggered arrangements is given by [1]

Nu = 0.33 Re0 6 Pr033 (15)

Substituting, we have the Reynolds, Nusselt, and Prandtl numbers

Re=(16)

Nu=M (17)

And

Pr = ^ (18)

K

Where

G = gas mass velocity, lb/ft2 h d = tube outer diameter, in. m = gas viscosity, lb/fth k = gas thermal conductivity, Btu/fth °F Cp = gas specific heat, Btu/lb °F

All the gas properties above are to be evaluated at the gas film temperature. Substituting Eqs. (16)-(18) into Eq. (15) and simplifying, we have

Hc = °.9G°’6 ^ (19)

Where

C0.33

F = k061 ^ (20)

Factor F has been computed for air and flue gases, and a good estimate is given in Table 8.3.

The gas mass velocity G is given by

W

G = 12 —————— (21)

NwL(St — d) v ;

Where

Nw = number of tubes wide ST = transverse pitch, in.

L = tube length, ft Wg = gas flow, lb/h

|

Table 8.3 F Factor for Air and Flue Gases

|

For quick estimates, gas film temperature f can be taken as the average of gas and fluid temperature inside the tubes.

Determine the gas-side convective heat transfer coefficient for a bare tube superheater tube of diameter 2.0 in. with the following parameters:

Gas flow = 150,000lb/h Gas temperature = 900°F Average steam temperature = 500°F Number of tubes wide =12 Length of the tubes = 10.5 ft Transverse pitch = 4.0 in.

Longitudinal pitch = 3.5in. (staggered)

Solution. Estimate G. From Eq. (21),

G =12 x -—»T9—r — = 7142 lb/ft2 h 12 x 10 . 5 x (4 — 2) ‘

Using Table 8.3, at a film temperature of 700°F, F = 0.113. Hence,

Hc = 0 . 9 x 71420 6 x 0143 = 15 . 8 Btu/ft2 h °F

Because the gas temperature is not high, the hN value will be low, so

U « ho « hc = 15 . 8 Btu/ft2 h °F

(Film temperature may be taken as the average of gas and steam temperatures, for preliminary estimates. If an accurate estimate is required, temperature drops across the various thermal resistances as discussed in Q8.16a must be determined.)

The convective heat transfer coefficient obtained by the above method or Grimson’s method can be modified to include the effect of angle of attack a of the gas flow over the tubes. The correction factor Fn is 1 for perpendicular flow and decreases as shown in Table 8.4 for other angles [1].

If, for example, hc = 15 and the angle of attack is 60°, then hc =

0. 94 x 15 = 14 .1 Btu/ft2 h °F.

|

Table 8.4 Correction Factor for Angle of Attack

|

8.05 Q:

How is the convective heat transfer coefficient for air and flue gases determined using Grimson’s correlation?

Grimson’s correlation, which is widely used for estimating hc [1], is

Nu = B x ReN (22)

Coefficient B and power N are given in Table 8.5.

150,0 lb/h of flue gases having an analysis (vol%) of CO2 = 12, H2O = 12, N2 = 70, and O2 = 6 flows over a tube bundle having 2 in. OD tubes at 4 in. square pitch. Tubes per row = 18; length = 10 ft. Determine hc if the fluid temperature is 353°F and average gas temperature is 700°F. The Appendix tables give the properties of gases.

At a film temperature of 0.5 x (353 + 700) = 526°F, Cp = 0.2695, m = 0.0642 and k = 0.02344. Then mass velocity G is

G = 12 x——— 150000———— = 5000 lb/ft2 h

18 x 10 x (4 — 2) ‘

|

Table 8.5 Grimson’s Values of B and N

|

5000 x 2

Re =—————— = 12,980

12 x 0.0642

H v 2

Nu = 0.229 x 12,980°•632 = 91 = ■ c

12 x 0.02344 or

2

Hc = 12 . 8 Btu/ft2 h °F

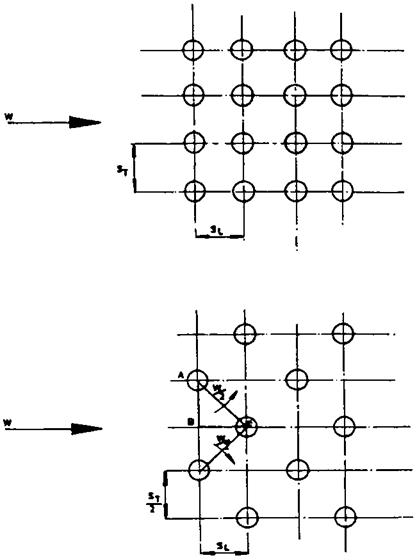

Compare in-line versus staggered arrangements of plain tubes from the point of View of heat transfer and pressure drop considerations. In a waste heat boiler

180,0 lb/h of flue gases at 880°F are cooled to 450°F generating steam at 150psig. The gas analysis is (vol%) CO2 = 7, H2O = 12, N2 = 75, and O2 = 6. Tube OD = 2 in.; tubes/row = 24; length = 7.5 ft. Compare the cases when tubes are arranged in in-line and staggered fashion with transverse pitch = 4 in. and longitudinal spacing varying from 1.5 to 3in.

Using Grimson’s correlation, the convective heat transfer coefficient hc was computed for the various cases. The nonluminous coefficient was neglected due to the low gas temperature. The surface area and the number of rows deep required were also computed along with gas pressure drop. The results are shown in Table 8.6.

Gas mass velocity G = „180 .00^X 12— = 6000 lb/ft2 h J 24 x (4 — 2) x 7 . 5

|

Table 8.6 In-Line Versus Staggered Arrangement of Bare Tubes

|

Average gas temperature = 0.5 x (880 + 450)/2 = 665°F, and film temperature is about 525°F.

Cp = 0.2706, m = 0.06479, k = 0.02367 at gas film temperature and Cp = 0.2753 at the average gas temperature.

6000 x 2 ,

Re =——————- = 15,434

12 x 0.06479

Duty Q = 180,000 x 0.99 x 0.2753 x (880 — 450) = 21 MMBtu/h Saturation temperature = 366°F.

(880 — 366) — (450 — 366)

AT = log-mean temperature difference = ■

Ln[(880 — 366)/(450 — 366)] = 237°F

With SL/d = 1.5 in-line, we have the values for B and N from Table 8.5:

B = 0.101 and N = 0.702 Hence

0.702 ——— ’ 2

Nu = 0.101 x 15,434 = 88.0 = hc x

12 x 0.02367

Or

Hc = 12.5

Because other resistances are small, U = 0.95hc = 11.87 Btu/ft2 h °F.

Hence

21 x 106

A = ———- —— = 7465 = 3.14 x 2 x 24 x 7.5Nd/12

237 x 11.87 d

Or the number of rows deep Nd = 79.

The friction factor f, using the method discussed in Q7.27, is

F = 15,434~°,15(0.044 + 0.08 x 1.5) = 0.0386

Average gas density = 0.0347 lb/ft3

_1(1 2 0.0386

Gas pressure drop = 9.3 x 10 10 x 60002 x 79 x————— = 2.95 in. WC

F F 0.0347

The calculations for the other cases are summarized in Table 8.6.

1. The staggered arrangement of bare tubes does not have a significant impact on the heat transfer coefficient when the longitudinal spacing exceeds 2, which is typical in steam generators. Ratios lower than 1.5 are not used, owing to potential fouling concerns or low ligament efficiency.

2. The gas pressure drop is much higher for the staggered arrangement. Hence, with bare tube boilers the in-line arrangement is preferred. However, with finned tubes, the staggered arrangement is comparable with the in-line and slightly better in a few cases. This is discussed later.

8.07a Q:

How is the nonluminous radiation heat transfer coefficient evaluated?

In engineering heat transfer equipment such as boilers, fired heaters, and process steam superheaters where gases at high temperatures transfer energy to fluid inside tubes, nonluminous heat transfer plays a significant role. During combustion of fossil fuels such as coal oil, or gas—triatomic gases—for example, water vapor, carbon dioxide, and sulfur dioxide—are formed, which contribute to radiation. The emissivity pattern of these gases has been studied by Hottel, and charts are available to predict gas emissivity if gas temperature, partial pressure of gases, and beam length are known.

Net interchange of radiation between gases and surroundings (e. g., a wall or tube bundle or a cavity) can be written as

|

|

(23)

Where

Sg = emissivity of gases at Tg

Ag = absorptivity at To

Tg = absolute temperature of gas, °R

To = absolute temperature of tube surface, °R

Sg is given by

|

(24) |

![]() Sg = Sc + ZSw — As

Sg = Sc + ZSw — As

Ag is calculated similarly at To. z is the correction factor for the water pressure, and As is the decrease in emissivity due to the presence of water vapor and carbon dioxide.

Although it is desirable to calculate heat flux by (23), it is tedious to estimate ag at temperature To. Considering the fact that T4 will be much smaller

Than Tg4, with a very small loss of accuracy we can use the following simplified equation, which lends itself to further manipulations.

|

(25) |

![]() Q = SЈg(Tg — T) = hN (Tg — To)

Q = SЈg(Tg — T) = hN (Tg — To)

The nonluminous heat transfer coefficient hN can be written as

![]() (26)

(26)

To estimate hN, partial pressures of triatomic gases and beam length L are required. L is a characteristic dimension that depends on the shape of the enclosure. For a bundle of tubes interchanging radiation with gases, it can be shown that

|

|

(27a)

L is taken approximately as 3.4-3.6 times the volume of the space divided by the

Surface area of the heat-receiving surface. For a cavity of dimensions a, b and c,

|

1. 7 |

|

L = |

|

2(ab + bc + ca) 1/a + 1/b + 1/c |

|

3 . 4 x abc |

|

|

In the case of fire tube boilers, L = di.

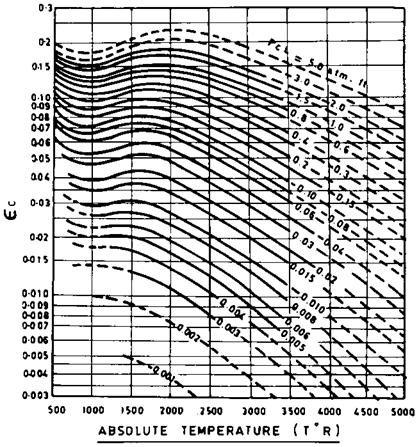

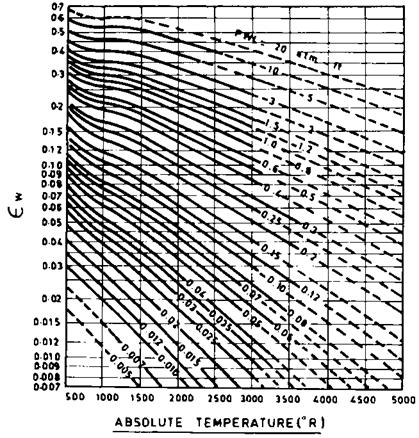

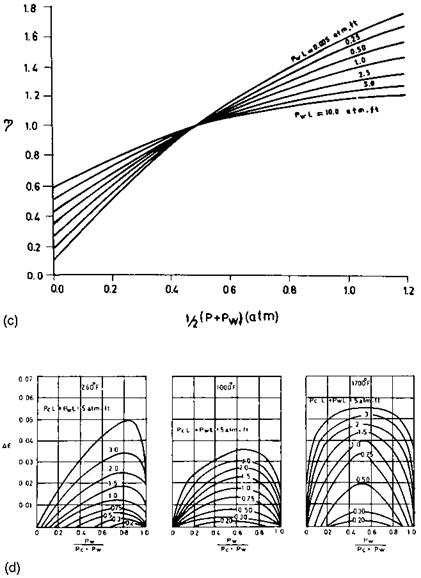

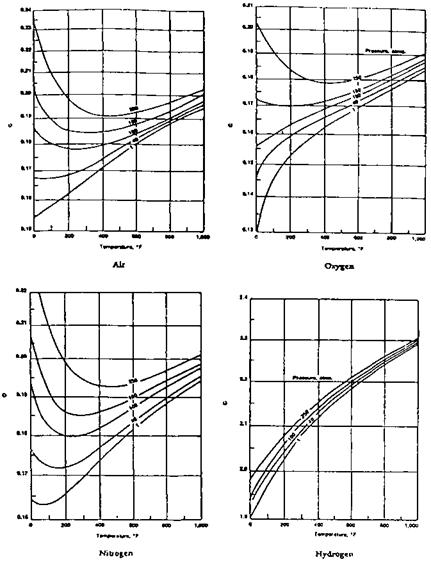

Sg can be estimated using Figs. 8.1a-8.1d, which give ec, ew, z, and As, respectively. For purposes of engineering estimates, radiation effects of SO2 can be taken as similar to those of CO2. Hence, partial pressures of CO2 and SO2 can be added and Fig. 8.1 used to get sc.

Determine the beam length L if ST = 5in., SL = 3.5 in., and d = 2 in.

Solution.

|

= 7.8 in. |

![]()

|

L = 1. 08 x |

![]() 5 x 3. 5 — 0 . 785 x 4

5 x 3. 5 — 0 . 785 x 4

2

In a fired heater firing a waste gas, CO2 in flue gases = 12% and H2O = 16%. The gases flow over a bank of tubes in the convective section where tubes are arranged as in Example 1 (hence L = 7.8). Determine hN if tg = 1650°F and to = 600°F.

|

FIgure 8.1a Emissivity of carbon dioxide. (From Ref 1.) |

Solution.

7.8

TOC o "1-5" h z PcL = 0.12 x — = 0.078 atm ft c 12

7 8

PwL = 0.16 x — = 0.104 atm ft w 12

In Fig. 8.1a at Tg = (1650 + 460) = 2110°R and PcL = 0.078, sc = 0.065. In Fig. 8.1b, at Tg = 2110°R and PwL = 0.104, sw = 0.05. IN Fig. 8.1c, corresponding to (P + Pw)/2 = 1.16/2 = 0.58 and PwL = 0.104, z = 1.1. In Fig. 8.1d,

|

FIgure 8.1b Emissivity of water vapor. (From Ref 1.) |

Corresponding to Pw/(Pc + Pw) = 0 .16/0 . 28 and (Pc + Pw)L = 0 .182, As : 0.002. Hence,

Sg = 0.065 + (1.1 x 0.05) — 0.002 = 0.118

Using Eq. (26) with the Boltzmann constant a = 0 .173 x 10-8,

21104 — 10604

|

2110 — 1060 |

![]() HN = 0 .173 x 10-8 x 0 .118 x ■ = 3. 6 Btu/ft2 h °F Thus, hN can be evaluated for gases.

HN = 0 .173 x 10-8 x 0 .118 x ■ = 3. 6 Btu/ft2 h °F Thus, hN can be evaluated for gases.

|

FIgure 8.1c, d (c) Correction factor for emissivity of water vapor. (d) Correction term due to presence of water vapor and carbon dioxide. (From Ref 1.) |

8.07b Q:

Can gas emissivity be estimated using equations?

Gas emissivity can be obtained as follows. hN is given by Eq. (26),

T4- t

1 g o

HN = asg ————-

N g T ______ T

Tg To

Where

A = Stefan-Boltzmann constant = 0.173 x 10 8 Tg and To = gas and tube outer wall temperature, °R

Sg, gas emissivity, is obtained from Hottel’s charts or from the expression

Eg = 0.9 x (1 — e-KL) (28a)

(0.8 +1.6pw)x(1 — 0.38Tg/1000)

K =——————— u,—————- r x (Fc +Fw) (28b)

V(pc +pw)L

Tg is in K. L is the beam length in meters, and pc and pw are the partial pressures of carbon dioxide and water vapor in atm. L, the beam length, can be estimated for a tube bundle by Eq. (27a),

L =1.08 x ST xSL -°.785d2

D

ST and SL are the transverse pitch and longitudinal pitch. Methods of estimating pc and pw are given in Chapter 5.

In a boiler superheater with bare tubes, the average gas temperature is 1600°F and the tube metal temperature is 700°F. Tube size is 2.0 in., and transverse pitch ST = longitudinal pitch SL = 4.0 in. Partial pressures of water vapor and carbon dioxide are pw = 0.12, pc = 0.16. Determine the nonluminous heat transfer coefficient.

From Eq. (27a), the beam length L is calculated.

4 x 4 — 0:785 x 2 x 2

L = 1.08 x———————————

2

= 6.9 in. = 0.176 m

Using Eq. (28b) with Tg = (1600 — 32)/1.8 + 273 = 1114 K, we obtain

(0.8 + 1.6 x 0.12) x(1 — 0.38 x 1.114) A

K =——————— . —————- x 0.28

0:28 x 0:176

= 0:721 From Eq. (28a),

Sg = 0.9 x [1 — exp(-0.721 x 0.176)] = 0.107 Then, from Eq. (26),

8 20604 — 11604

HN = 0.173 x 0.107 x 10-8 x 1600 — 700 = 3.33 Btu/ft2 h °F

8.08a Q:

How is heat transfer in a boiler furnace evaluated?

Furnace heat transfer is a complex phenomenon, and a single formula or correlation cannot be prescribed for sizing furnaces of all types. Basically, it is an energy balance between two fluids—gas and a steam-water mixture. Heat transfer in a boiler furnace is predominantly radiation, partly due to the luminous part of the flame and partly due to nonluminous gases. A general approximate expression can be written for furnace absorption using an energy approach:

Qf = ApSw Sf s(Tg — To4)

= Wf LHV — Wghe )

Gas temperature (Tg) is defined in many ways; some authors define it as the exit gas temperature itself. Some put it as the mean of the theoretical flame temperature and te. However, plant experience shows that better agreement between measured and calculated values prevails when tg = tc + 300 to 400°F [1]. The emissivity of a gaseous flame is evaluated as follows [1]:

Sf = p(1 — e-KPL) (30)

P characterizes flame-filling volumes.

P = 1.0 for nonluminous flames = 0.75 for luminous sooty flames of liquid fuels = 0.65 for luminous and semiluminous flames of solid fuels L = beam length, m

К = attenuation factor, which depends on fuel type and presence of ash and its concentration. For a nonluminous flame it is

K = 0-8 + (1 — 0.38Te/1000) (pc + pw) (28b)

V(pc + pw)L

For a semiluminous flame, the ash particle size and concentration enter into the calculation:

0 :8 + 1 :6pw

K = , (1 — 0.38Te/1000) (pc + pw)

V(pc + pw)L

1 ‘/3

Where

Dm = the mean effective diameter of ash particles, in mm dm = 13 for coals ground in ball mills

= 16 for coals ground in medium — and high-speed mills = 20 for combustion of coals milled in hammer mills m = ash concentration in g/N m3 Te = furnace exit temperature, K

For a luminous oil or gas flame,

K=їж — 05 <28d>

Pw and pc are partial pressures of water vapor and carbon dioxide in the flue gas.

The above equations give only a trend. A wide variation could exist due to the basic combustion phenomenon itself. Again, the flame does not fill the furnace fully. Unfilled portions are subjected to gas radiation only, the emissivity of which (0.15-0.30) is far below that of the flame. Hence, decreases. Godridge reports that in a pulverized coal-fired boiler, emissivity varied as follows with respect to location [3]:

TOC o "1-5" h z Excess air 15% 25%

Furnace exit 0.6 0.5

Middle 0.7 0.6

Also, furnace tubes coated with ferric oxide have emissivities, sw, of the order of

0. 8, depending on whether a slag layer covers them. Soot blowing changes sw considerably. Thus, only an estimate of Sf and sw can be obtained, which varies with type of unit, fuel, and operation regimes.

To illustrate these concepts, a few examples are worked out. The purpose is only to show the effect of variables like excess air and heat release rates on furnace absorption and furnace exit gas temperature.

Determine the approximate furnace exit gas temperature of a boiler when net heat input is about 2000 x 106Btu/h, of which 1750 x 106Btu/h is due to fuel and the rest is due to air. HHV and LHV of coals fired are 10,000 and 9000 Btu/lb, respectively, and a furnace heat release rate of 80,000 Btu/ft2h (projected area basis) has been used. The values sw and Sf may be taken as 0.6 and 0.5, respectively; 25% is the excess air used. Water-wall outer temperature is 600°F. Ash content in coal is 10%.

Solution.

Q LHV

Q = 80,000 = Wf ——

Ap f Ap

From combustion calculation methods discussed in Chapter 5, using 1 MMBtu fired basis, we have the following ratio of flue gas to fuel:

Wg 760 x 1.24 x 104 | 1 10

Wf = 10 + 1 — 100

= 10.4 lb/lb

Q = APSwSf s (Tg — T4) = Wf LHV — Wghe

Dividing throughout by Wf gives A

Wf SwSf S(Tg — T) = LHV — W/e

Ap/Wf = LHV/80,000 = 0.1125

Assume te = 1900°F. Then

Cpm = 0.3 Btu/lb °F

Tg = 1900 + 300 = 2200° F = 2660°R

Let us see if the assumed te is correct. Substituting for Ap /Wf, sw, Sf, s, Tg, Te in the above equation, we have (LHS = left-hand side; RHS = right-hand side)

LHS = 0.1125 x 0.6 x 0.5 x 0.173 x (26.64 — 10.64) = 2850 RHS = (9000 — 10.4 x 1900 x 0.3) = 3072

These do not tally, so we try te = 1920°F. Neglect the effect of variation in Cpm:

LHS = 0.1125 x 0.6 x 0.5 x (26.84 — 10.64) x 0.173 = 2938 RHS = 9000 — 1920 x 0.3 x 10.4 = 3009

These agree closely, so furnace exit gas temperature is around 1920°F. Note that the effect of external radiation to superheaters has been neglected in the energy balance. This may give rise to an error of 1.5-2.5% in te, but its omission greatly simplifies the calculation procedure. Also, losses occurring in the furnace were omitted to simplify the procedure. The error introduced is quite low.

It is desired to use a heat loading of 100,000 Btu/ft2 h in the furnace in Example

1. Other factors such as excess air and emissivities remain unaltered. Estimate the furnace exit gas temperature.

Solution.

Q LHV

Q = 100,000 = wf ——

Ap f Ap

Al = ^HV_ = 0.09

Wf 100,000

W„

= 10.4, te = 2000°F; tg = 2300°F

Wf g

Cpm = 0.3 Btu/lb °F; Tg = 2300 + 460 = 2760°R LHS = 0.09 x 0.6 x 0.5 x 0.173 x (27.64 — 10.64) = 2664 RHS = (9000 — 10.4 x 2000 x 0.3) = 2760

From this it is seen that te will be higher than assumed. Let te = 2030°F, Tg = 2790°R

Then

LHS = 0.09 x 0.6 x 0.5 x 0.173

X [(27.9)4 — (10.6)4] = 2771 RHS = 9000 — 10.4 x 2030 x 0.3 = 2667

Hence, te will lie between 2000 and 2030°F, perhaps 2015°F.

The exercise shows that the exit gas temperature in any steam generator will increase as more heat input is given to it; that is, the higher the load of the boiler, the higher the exit gas temperature. Example 3 shows the effect of excess air on

Te-

What will be the furnace exit gas temperature when 40% excess air is used instead of 25%, heat loading remaining at about 100,000 Btu/ft2h in the furnace mentioned in earlier examples?

Solution.

Q LHV Ap

Q = 100,000 = Wf ——, — p = 0.09

Ap f Ap Wf

Wg 760 x 1.4 x 104

W =———— 106——- + 09 = 1L54lb/lb

Te = 1950°F, Cpm = 0.3 Btu/lb °F

Tg = 1950 + 300 + 460 = 2710°R

LHS = 0.09 x 0.6 x 0.5 x 0.173

X [(27.1)4 — (10.6)4] = 2460 RHS = 9000 — (11.54 x 1950 x 0.3) = 2249

These nearly tally; hence, te is about 1950°F, compared to about 2030°F in Example 2. The effect of the higher excess air has been to lower te.

If ew x Јf = 0.5 instead of 0.3, what will be the effect on te when heat loading is

100,0 Btu/ft2h and excess air is 40%?

Solution. Let

Te = 1800°F; Tg = 1800 + 300 + 460 = 2560°R LHS = 0.09 x 0.5 x 0.173 x [(25.6)4 — (10.6)4]

= 3245

RHS = 9000 — (11.54 x 1800 x 0.3) = 2768

Try

Te = 1700°F; Tg = 2460°R

LHS = 0.09 x 0.5 x 0.173 x [(24.6)4 — (10.6)4]

= 2752

RHS = 9000 — (11.54 x 1700 x 0.3) = 3115

Try

Te = 1770°F; Tg = 2530°R

Then

LHS = 3091; RHS = 2872

Hence, te will be around 1760°F. This example shows that when surfaces are cleaner and capable of absorbing more radiation, te decreases.

In practice, furnace heat transfer is not evaluated as simply as shown above Because of the inadequacy of accurate data on soot emissivity, particle size, distribution, flame size, excess air, presence and effect of ash particles, etc. Hence, designers develop data based on field tests. Estimating te is the starting point for the design of superheaters, reheaters, and economizers.

Some boiler furnaces are equipped with tilting tangential burners, whereas some furnaces have only front or rear nontiltable wall burners. The location of the burners affects te significantly. Hence, in these situations, correlations with practical site data would help in establishing furnace absorption and temperature profiles. (See also p. 112, Chapter 3.)

A promising technique for predicting furnace heat transfer performance is the zone method of analysis. It is assumed that the pattern of fluid flow, chemical heat release, and radiating gas concentration are known, and equations describing conservation of energy within the furnace are developed. The furnace is divided into many zones, and radiation exchange calculations are carried out.

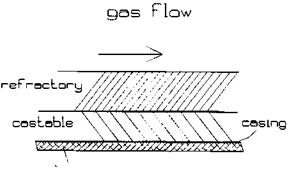

How is heat transfer evaluated in unfired furnaces?

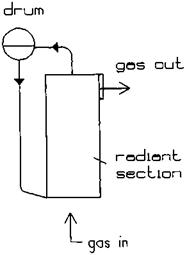

Radiant sections using partially or fully water-cooled membrane wall designs are used to cool gas streams at high gas temperatures (Fig. 8.2). They generate saturated steam and may operate in parallel with convective evaporators if any. The design procedure is simple and may involve an iteration or two. The higher the partial pressures of triatomic gases, the higher will be the nonluminous radiation and hence the duty.

|

Figure 8.2 Radiant furnace in a water tube boiler. |

If a burner is used as in the radiant section of a furnace-fired HRSG, the emissivity of the flame must also be considered. As explained elsewhere [8], radiant sections are necessary to cool the gases to below the softening points of any eutectics present so as to avoid bridging or slagging at the convection section. They are also required to cool gases to a reasonable temperature at the superheater if it is used.

200,0 lb/h of flue gases at 1800°F has to be cooled to 1600°F in a radiant section of a waste heat boiler of cross section 9 ft x 11 ft. Saturated steam at 200 psig is generated. Determine the furnace length required. Flue gas analysis is (vol%) CO2 = 8, H2O = 18, N2 = 72, O2 = 2. Assume a length of 25 ft and that the furnace is completely water-cooled.

Surface area for cooling = (11 + 9)x2 x 25 = 1000 ft volume

Beam length = 3.4 x

Surface area

9 x 11 x 25

= 3.4 x———————————————— = 7.1 ft = 2.15 m

2 x (11 x 9 + 9 x 25 + 11 x 25)

Average gas temperature = 1700°F = 1200 K. Partial pressure of CO2 = 0.08, and that of H2O = 0.18. Using Eq. (28b),

|

|

K = (0.8 + 1.6 x 0.18)(1 — 0.38 x 1.2) x

Gas emissivity sg = 0.9 x (1 — e-0’2053 x 2 16) = 0.32 23

Let the average surface temperature of the furnace be 420°F (saturation temperature plus a margin). Then the energy transferred is

Qr = 0.173 x 0.9 x 0.3223 x (21.64 — 8.84) x 1000 = 10.63 MM Btu/h

Required duty = 200,000 x 0.99 x 0.32 x 200 = 12.67 MM btu/h

Where 0.32 is the gas specific heat. Hence the furnace should be longer. The beam length and hence the gAs emissivity will not change much with change in furnace length; therefore one may assume that the furnace length required = (12.67/10.63) x 25 = 29.8 or 30 ft.

If the performances at other gas conditions are required, a trial-and-error procedure is warranted. First the exit gas temperature is assumed; then the energy transferred is computed as shown above and compared with the assumed duty.

How is the distribution of external radiation to tube bundles evaluated? Discuss the effect of tube spacing.

Tube banks are exposed to direct or external radiation from flames, cavities, etc., in boilers. Depending on the tube pitch, the energy absorbed by each row of tubes varies, with the first row facing the radiation zone receiving the maximum energy. It is necessary to compute the energy absorbed by each row, particularly in superheaters, because the contribution of the radiation can result in high tube wall temperatures.

The following formula predicts the radiation to the tubes [8].

![]() (31)

(31)

Where a is the fraction of energy absorbed by the first row. The second row would then absorb (1 — a)a; the third row, {1 — [a + (1 — a)a]}a; and so on.

1 MM Btu/h of energy from a cavity is radiated to a superheater tube bank that has 2 in. OD tubes at a pitch of 8 in. If there are six rows, estimate the distribution of energy to each row.

Solution. Substituting d = 2, S = 8 into Eq. (31), we have

|

2/8 2 |

![]()

|

A = 3.14 |

![]() Sin 1 ( + p4 x 4 — 1 — 2

Sin 1 ( + p4 x 4 — 1 — 2

28

= 0.3925 — 0.25(0.2526 + VT5 — 4) = 0.361

Hence the first row absorbs 0.361 MM Btu/h.

The second row would receive (1 — 0.361) x 0.361 = 0.231 or 0.231 MM Btu/h.

The third row receives [1 — (0.361 + 0.231)] x 0.361 = 0.147 MM Btu/h.

The fourth row, [1 — (0.361 + 0.231 + 0.147)] x 0.361 = 0.094 MM Btu/h, and so on.

It can be seen that the first row receives the maximum energy and the amount lessens as the number of rows increases. For a tube pitch S of 4 in., a = 0.6575. The first row receives 0.6575 MM Btu/h; the second, 0.225 M Btu/h; and the third, 0.077 MM Btu/h. Hence if the tube pitch is small, a large amount of energy is absorbed within the first two to three rows, resulting in high heat flux in those tubes and consequently high tube wall temperatures. Hence it is better to use a wide pitch when the external radiation is large so that the radiation is spread over more tubes and the intensity is not concentrated within two or three tubes. Screen tubes in boilers and fired heaters perform this function.

A soot blower lance is inserted in a boiler convection section where hot flue gases at 2000°F are flowing around the tubes. If the water wall enclosure is at 400°F, what will be the lance temperature? Assume that the heat transfer coefficient between the flue gas and the lance is 15Btu/ft2h °F and the emissivity of the lance and the water wall tubes is 0.9.

The energy transferred between the flue gases and lance and from the lance to the water wall enclosure in Btu/ft2 h is given by

Q = hc(2000 — T)

= 0.173 x 0.9 x 0.9 x [(T + 460)4 — (400 + 460)4] x 10-8

Where

T = lance temperature, °F

0.173 x 10- 8 is the radiation constant

Emissivity of lance and enclosure = 0.9

Actually, a trial-and-error procedure is required to solve the above equation. However, it may be shown that at T = 1250°F, both sides balance and Q = 11,250 BtU/ft2 h. At low loads, when hc = 5 and with other parameters remaining the same, what will be the lance temperature? It can be shown to be about 970°F and Q = 5150btu/ft2h.

Hence just as a thermocouple reads a lower temperature due to the radiation to the enclosure, the lance also will not reach the gas temperature. Its temperature will be lower than that of the gas.

Determine the size of a fire tube waste heat boiler required to cool 100,000 lb/h of flue gases from 1500°F to 500°F. Gas analysis is (vol%) CO2 = 12, H2O = 12, N2 = 70, and O2 = 6; gas pressure is 5in. WC. Steam pressure is 150psig, and feedwater enters at 220°F. Tubes used are in 2 in. OD x 1.77 in. ID; fouling factors are gas-side fouling factor (ft); 0.002 ft2 h °F/Btu and steam-side ff = 0.001 ft2h°F/Btu. Tube metal thermal conductivity = 25Btu/fth°F. Steam — side boiling heat transfer coefficient = 2000 Btu/ft2 °F. Assume that heat losses and margin = 2% and blowdown = 5%.

Use Eq. (4) to compute the overall heat transfer coefficient, and then arrive at the size from Eq. (1).

![]() Hdo/d), _L

Hdo/d), _L

24Km h0

Hi, the tube-side coefficient, is actually the sum of a convective portion hc plus a nonluminous coefficient hn. hc is obtained from Q8.04:

C

Hc = 2.44 x w08 x —r-T c d/’8

At the average gas temperature of 1000°F, the gas properties can be shown to be Cp = 0.287 Btu/lb °F, m = 0.084 lb/fth, and k = 0.0322 Btu/fth °F. Hence,

C = x (0.0322)0-6 = 0.208

�.084/ v ’

Boiler duty Q = 100,000 x 0.98 x 0.287 x (1500 — 500)

= 28.13 x 106 Btu/h

Enthalpies of saturated steam, saturated water, and feedwater from steam tables are 1195.5, 338, and 188 Btu/lb, respectively. The enthalpy absorbed by steam is then (1195.5 — 188) + 0.05 x (338 — 188) = 1015Btu/lb, where 0.05 is the blowdown factor corresponding to 5% blowdown.

Hence,

28:13 106 ……………….

Steam generation =—————— = 27,710 lb/h

In order to compute ht, the flow per tube w is required. Typically w ranges from 100 to 200lb/h for a 2 in. tube. Let us start with 600 tubes; hence w = 100,000/600 = 167 lb/h.

1670:8

Hc = 2.44 x 0.208 x———— ^ = 10.9 Btu/ft2 h °F

C (1.77)

The nonluminous coefficient is usually small in fire tube boilers because the beam length corresponds to the tube inner diameter. However, the procedure used in Q8.07 can also be used here. Let us assume that it is 0.45 Btu/ft2h °F. Then

Ht = 10.90 + 0.45 = 11.35 Btu/ft2 h °F

Let us compute U. Because it is based on tube outside surface, let us call it U0.

1 2/1 77 2

W0 = iL^T + °-°01 + 0.002 x 177

+ ^(177) x 24xx25 + 0.0005

= 0.10 + 0.001 + 0.00226 + 0.00041 + 0.0005 = 0 .10417

Hence, U0 = 9.6 Btu/ft2 h °F.

The various resistances in ft2h °F/Btu are

|

Gas-side heat transfer |

0.10 |

|

Gas-side fouling |

0.00226 |

|

Metal resistance |

0.00041 |

|

Steam-side fouling |

0.001 |

|

Steam-side heat transfer |

0.0005 |

If U is computed on the basis of tube inner surface area, then U is given by the expression

Ai x Ui = Ao x Uo

Hence,

U = 9 . 6 x — = 10 . 85 Btu/ft2 h °F

I 1. 77 ‘

Log-mean temperature difference is

(1500 — 366) — (500 — 366) _ ln[(1500 — 366)/(500 — 366)]

Hence

Ao = 28 J3 x 106 = 6261 ft2

0 468 x 9. 6

= 3 .14 x 2 x 600 x —

12

So required length L of the tubes = 19.93 ft. Use 20 ft. Then

20 2 A0 = 3 .14 x 2 x 600 x — = 6280 ft2

0 12

Ai 5558 ft2

Let us compute the gas pressure drop using Eq. (12) of Chapter 7.

DPg = 93 x 10~6 x w2/Le-j5

Friction factor f depends on tube inner diameter and can be taken as 0.02. The equivalent length Le can be approximated by L + 5dt to include the tube inlet and exit losses.

Specific volume v obtained as 1/density, or v = 1/p. Gas density at the average gas temperature of 1000°F is pg = 39/1460 = 0.0267 lb/cu ft. Therefore,

DPg = 93 x 10~6 x 1672 x 0.02

X 20 + 5 xL775 = 3.23 in. WC

0. 0267 x (1.77)5

This is only one design. Several variables such as tube size and mass flow could be changed to arrive at several options that could be reviewed for optimum operating anD iNstalled costs.

8.11 Q:

What is the effect of tube size and gas velocity on boiler size? Is surface area the sole criterion for boiler selection?

Surface area should not be used as the sole criterion for selecting or purchasing boilers, because tube size and gas velocity affect this variable.

Shown in Table 8.7 are the design options for the same boiler duty using different gas velocities and tube sizes; the procedure described in Q8.10 was used to arrive at these options. The purpose behind this example is to bring out the fact that surface area can vary by as much as 50% for the same duty.

1. As the gas velocity increases, the surface area required decreases, which is obvious.

2. The smaller the tubes, the higher the heat transfer coefficient for the same gas velocity, which also decreases the surface area.

3. For the same gas pressure drop, the tube length is smaller if the tube size is smaller. This fact helps when we try to fit a boiler into a small space.

4. For the same tube size, increasing the gas velocity results in a longer boiler, a greater gas pressure drop, but smaller surface area.

In the case of water tube boilers, more variables such as tube spacing and in-line or staggered arrangement in addition to gas velocity and tube size can affect surface area. This is discussed elsewhere.

|

Tube size |

1.75 x 1.521 |

2 x 1.773 |

2.5 x 2.238 |

||||||

|

Velocity, ft/s |

109 |

141 |

166 |

110 |

140 |

165 |

109 |

140 |

166 |

|

Tubes |

1100 |

850 |

725 |

800 |

630 |

535 |

510 |

395 |

335 |

|

Length, ft |

19 |

20 |

21 |

22.5 |

24 |

25 |

29.5 |

31.5 |

33 |

|

Surface area, ft2 |

8318 |

6766 |

6059 |

8351 |

7015 |

6205 |

8811 |

7286 |

6474 |

|

U, Btu/ft2 h °F |

9.74 |

11.78 |

13.25 |

9.6 |

11.43 |

12.89 |

9.15 |

11.02 |

12.43 |

|

Pressure drop in. WC |

2.5 |

4.4 |

6.3 |

2.6 |

4.4 |

6.2 |

2.5 |

4.3 |

6.2 |

Gas flow = 110,000lb/h; inlet temperature = 1450°F; exit temperature = 500°F; steam pressure = 300psig; feedwater in = 230°F; blowdown = 5%; steam = 28,950 lb/h; gas analysis (vol%): CO2 = 7, H2O = 12, N2 = 75, O2 = 6; boiler duty = 29.4 MM Btu/h.

How is the tube wall temperature in fire tube boilers evaluated? Discuss the importance of heat flux.

To compute the tube wall temperatures, heat flux must be known. qo = heat flux outside tubes = Uo x (tg — t,) Btu/ft2 h

Similarly, qt (heat flux inside the tube) would be U x (tg — t,). However, heat flux outside the tubes is relevant in fire tube boilers because boiling occurs outside the tubes, whereas in water tube boilers the heat flux inside the tubes would be relevant. A high heat flux can result in a condition called departure from nucleate boiling (DNB), which will result in overheating of the tubes. It is preferable to keep the actual maximum heat flux below the critical heat flux, which varies from 150,000 to 250,000 Btu/ft2 h depending on steam quality, pressure, and tube condition [1].

An electrical analogy can be used in determining the tube wall temperatures. Heat flux is analogous to current, electrical resistance to thermal resistance, and voltage drop to temperature drop. Using the example worked in Q8.10, we have that at average gas conditions the product of current (heat flux) and resistance (thermal resistance) gives the voltage drop (temperature drop):

Qo = heat flux = 9.6 x (1000 — 366) = 6086 Btu/ft2 h

Temperature drop across gas film = 6086 x 0:1 = 609°F Temperature drop across gas-side fouling = 6086 x 0.00226 = 14°F Temperature drop across tube wall = 6086 x 0:00041 = 3°F Temperature drop across steam-side fouling = 6086 x 0:001 = 6°F Temperature drop across steam film = 6085 x 0:0005 = 3°F

Hence,

Average inside tube wall temperature = 1000 — 609 — 14 = 377°F Outside tube wall temperature = 377 — 3 = 347°F.

The same results are obtained working from the steam side.

Outside tube wall temperature = 366 + 6 + 3 = 375°F

One can also compute the maximum tube wall temperature by obtaining the heat flux at the hot gas inlet end.

8.13 Q:

What is the effect of scale formation on tube wall temperatures?

If nonsoluble salts such as calcium or magnesium salts or silica are present in the feedwater, they can deposit in a thin layer on tube surfaces during evaporation, thereby resulting in higher tube wall temperatures.

Table 8.8 lists the thermal conductivity k of a few scales. Outside fouling factor ff0 can be obtained if the scale information is available.

Thickness of scale

Ff =—————————

O conductivity

Let us use the same example as in Q8.10 and check the effect of ff0 on boiler duty and tube wall temperatures. Let a silicate scale of thickness 0.03 in. be formed. Then,

Ff0 = M3 = 0.05 ft2 h °F/Btu

0.6

|

Table 8.8 Thermal Conductivities of Scale Materials

|

Assume that other resistances have not changed. (Because of different duty and gas temperature profile, the gas-side heat transfer coefficient will be slightly different. However, for the sake of illustration, we neglect this.) We have

-L = 0.10 + 0.00226 + 0.00041 + 0.05 + 0.0005

Uo

= 0.15317

Hence, Uo = 6.52 Btu/ft2 h °F

Heat flux qo = 6.52 x (1000 — 366) = 4133 Btu/ft2 h

Temperature drop across outside steam film = 0:0005 x 4133

= 2°F

Temperature drop across steam-side fouling layer or scale = 4133 x 0:05

= 207°F

Temperature drop across tube wall = 4133 x 0.00041

= 2°F

We see that average tube wall temperature has risen to 366 + 2 + 207 + 2 = 577°F from an earlier value of about 375°F. Scale formation is a serious problem. Note that the heat flux is now lower, but that does not help. At the front end, where the heat flux is higher, the tubes would be much hotter.

Now let us check the effect on boiler duty. It can be shown [1,8] that

Ln sat = ——— UA (32)

Tg2 tsat Wg x CP x hlf

Where hlf is the heat loss factor. If 2% losses are assumed, then hlf = 0.98.

We know that Uo = 6.52, Ao = 6280, tg1 = 1500, tsat = 366. Hence,

1500 — 366 6.52 x 6280

Ln-

Tg2 — 366 100,000 x 0.98 x 0.287

= 1.456

Or

1500 — 366 = 4.29 tg2 — 366

Hence tg2 = 630°F compared to 500°F earlier. The reason for tg2 going up is the lower Uo caused by scale formation.

Hence new duty = 100,000 x 0.98 x 0.287 x (1500 — 630) = 24.47 x 106 Btu/h. The decrease in duty is 28.13 — 24.47 = 3.66MMBtu/h. Even assuming

A modest energy cost of $3/MM Btu, the annual loss due to increased fouling is 3.66 x 3 x 8000 = $87,800. The steam production in turn gets reduced.

Plant engineers should check the performance of their heat transfer equipment periodically to see if the exit gas temperature rises for the same inlet gas flow and temperature. If it does, then it is likely due to fouling on either the gas or steam side, which can be checked. Fouling on the gas side affects only the duty and steam production, but fouling on the steam side increases the tube wall temperature in addition to reducing the duty and steam production.

To ensure that variations in exit gas temperature are not due to fouling but are due to changes in gas flow or temperature, one can use simulation methods. For example, if, for the same gas flow, the inlet gas temperature is 1800°F, we can expect the exit gas temperature to rise. Under clean conditions, this can be estimated using the equation (32)

1500 — 366 1800 — 366

————— =—————— , or tg2 = 535 F

500 — 366 tG2 — 366 g2

Now if, in operation, the exit gas temperature were 570-600°F, then fouling could be suspected; but if the gas temperature were only about 535°F, this would only be due to the increased gas inlet temperature. Similarly, one can consider the effect of gas flow and saturation temperature.

How is the size of a water tube boiler determined?

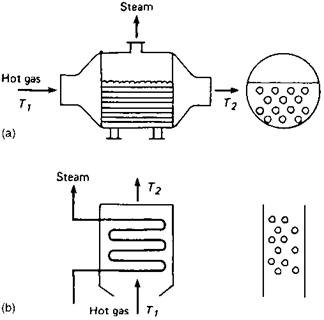

The starting point in the design of an evaporator (Fig. 8.3) is the estimation of the overall heat transfer coefficient U. The cross-sectional data such as the number of tubes wide, spacing, and length of tubes are assumed. From the duty and log — mean temperature difference, the surface area is obtained. Then the number of rows deep is estimated. Tube wall temperature calculations and gas pressure drop evaluation then follow. A computer program is recommended to perform these tedious calculations, particularly if several alternatives have to be evaluated.

200,0 lb/h of clean flue gas from an incinerator must be cooled from 1100°F to 600°F in a bare tube evaporator. Steam pressure = 250psig saturated. Feedwater temperature = 230°F. Blowdown = 5%. Fouling factors on steam — and gas-side = 0.001 ft2 h°F/Btu. Gas analysis (vol%): CO2 = 7, H2O = 12, N2 = 75,

O2 = 6. Let heat loss from casing = 1%.

|

FIgure 8.3 Boiler evaporator bundle. |

S0luti0n: Use 2 x 1.773 in carbon steel tubes; number wide = 24; length = 10 ft; tube spacing = 4 in. square.

Average gas temperature = 0.5 x (1100 + 600) = 850°F

Steam temperature inside tubes = 406°F. Assume tube wall temperature = 410°F (this should be checked again later).

Film temperature = 0.5 x (850 + 410) = 630°F

Gas properties at film temperature are (from Appendix) Cp = 0.2741, m = 0.0693, k = 0.0255

Cp at average gas temperature = 0.282

Duty Q = 200,000 x 0.99 x 0.282 x (1100 — 600) = 27.92 MMBtu/h Steam enthalpy change = (1201.7 — 199) + 0.05 x (381.4 — 199) = 1011.82 Btu/lb

Hence

Steam generation = 27.92 x = 27,600 lb/h

6 1011.82 ‘

Gas mass velocity G = —200,000 x 12 = 4167 lb/ft[2] h

24 x 12 x (4 — 2)

4167 x 2

Reynolds number Re = Gd/12m = ——— ^ = 10,021

J 12 x 0.0693

Using Grimson’s correlation,

Nu = 0.229 x (10,021)0 632 = 77.3 The convective heat transfer coefficient

Hc = Nu x 12k = 77.3 x 12 x 00255 = 11.83 Btu/ft2 h °F d 2

Let us compute the nonluminous heat transfer coefficient hN. Partial pressures of CO2 and H2O are 0.06 and 0.12, respectively; beam length L = 1.08 x (4 x 4 — 0.785 x 4)/2 = 6.95 in. = 0.176 m.

Average gas temperature = 850°F = 727 K

Using Eq. (28b),

^ (0.8 + 1.6 x 0.12) x(1 — 0.38 x 0.727) x 0.19 ^

K =—————————————- jrr———————— = 0.746

(0.19 x 0.176)

Gas emissivity eg = 0.9 x (1 — e-0’746×0 176) = 0.1107 Assuming that the tube wall is at 420°F (to be checked later)

13 14 8 8[3]

HN = 0.173 x 0. 9 x 0.1107 x —————— — = 0.94 Btu/ft2 h °F

N 1310 — 880 ‘

Using a conservative boiling heat transfer coefficient of 2000 Btu/ft2 h and a tube thermal conductivity of 25 Btu/ft h °F; we have

Or

(1100 — 406) — (600 — 406)

Log-mean temperature difference = —————————————— — —

5 F ln[(1100 — 406)/(600 — 406)]

= 393°F

27 92 x 106 2

Surface area required A = —; = 5776 ft

4 12 . 3 x 393

A = 3.14 x 2 x Nd x 24 x 12/12 = 5776, or Nd = 38 . 4

Use 40 rows deep. Surface provided = 6016 ft2. Let us estimate the gas pressure drop.

28 2 492

Gas density p =———- ^————— = 0 . 0295 lb/ft

* F 359 x (460 + 850) ‘

Friction factor f = 10,020-a15 x (0.044 + 0.08 x 2) = 0.0512

2 0.0512

AP„ = 9 . 3 x 10-10 x 41672 x 40 x—————- = 1.12 in. WC

G 0.0295

The average heat flux on tube ID basis is

Q = 12.3 x (850 — 406) x 2/1.773 = 6160 Btu/ft2 h

Temperature drop across inside fouling layer = 6160 x 0.001 = 62°F Temperature drop across inside film coefficient = 6160/2000 = 3.1 °F Drop across tube wall = 0.0004 x 1.773 x 6160/2 = 2.2°F

Hence tube outer wall temperature = 406 + 6.2 + 3.1 + 2.2 = 418°F. Since this is close to the assumed value another iteration is not necessary.

Note that this is only the average tube wall temperature. The maximum heat flux is at the gas inlet, and one has to redo these calculations to obtain the maximum tube wall temperature. A computer program would help speed up these calculations.

8.15a

Q:

How is the off-design performance of a boiler evaluated? Predict the performance of the boiler designed earlier under the following conditions: Gas flow =

230,0 lb/h; gas inlet temperature = 1050°F; steam pressure = 200psig. Gas analysis remains the same.

Performance calculations are more involved than design calculations, because we do not know the gas exit temperature. The NTU method discussed in Q8.30 minimizes the number of iterations. However, for an evaporator, a simple procedure exists for predicting the performance.

The boiler duty Q is given by the expression

Q = WgCp(t1 — t2) = UA(tf~ <2) (33)

Ln[(t1 — ts)/(t2 — ts)]

Where

Ti, t2 = gas inlet and exit temperatures, °F ts = saturation temperature, °F Wg = gas flow, lb/h (correcting for heat loss factor)

Cp = gas specific heat at average gas temperature, Btu/lb °F U = overall heat transfer coefficient, Btu/ft2h °F A = surface area, ft2

Simplifying, we have

T!—s = _^L (34)

T2 — ts WgCp ‘ ’

First we have to estimate U. Assuming 580°F as the gas exit temperature, average gas temperature = 815°F and average film temperature = 613°F.

M = 0.06875, k = 0.0252, Cp = 0.2735 Cp at average gas temperature = 0.28 Btu/lb °F

12 2

G = 230,000 x ——- —- = 4791 lb/ft2 h

24 x 12 x 2

4791 x 2

Re =——————— = 11,615

12 x 0.06875

Nu = 0.229 x 11, 6150 632 = 84.9

Or

Hc = 84.8 x 12 x 0.0252/2 = 12.9 Btu/ft2 h °F

The nonluminous heat transfer coefficient may be computed as before and shown to be 0.895 Btu/ft2 h °F.

1 = 1/(0.895 + 12.9) + 0.001 + 0.0011 + 0.000565 + 0.0004 = 0.0756

U = 13.2 Btu/ft2 h °F

Using Eq. (34) with saturation temperature of 388°F, we have 1050 — 388 13.2 x 6016 1 5

T2 — 388 = 230,000 x 0.99 x 0.28 = .

Or

T2 = 578°F From eq. (32)

Q = 230,000 x 0.99 x 0.28 x (1050 — 578) = 30.0 MM Btu/h

Steam generation = 29,770 lb/h

The tube wall temperature and gas pressure drop may be computed as before. It may be shown that the gas pressure drop is 1.5 in. WC and the tube wall temperature is 408°F. Thus off-design performance is predicted for the evaporator. With an economizer or superheater, More calculations are involved as the water or steam temperature changes. Also, the duty is affected by the configuration of the exchanger, whether counterflow, parallel flow, or crossflow. The NTU method discussed in Q8.29 and Q8.30 may be used to predict the off-design performance of such an exchanger.

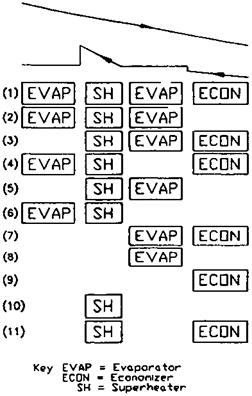

Discuss the logic for determining the off-design performance of a water tube waste heat boiler with the configuration shown in Fig. 8.4.

In the design procedure one calculates the size of the various heating surfaces such as superheaters, evaporators, and economizers by the methods discussed earlier based on the equation A = Q/(U x AT). In this situation, the duty Q, log — mean temperature difference AT, and overall heat transfer coefficient U are known or can be obtained easily for a given configuration.

In the off-design procedure, which is more involved, the purpose is to predict the performance of a given boiler under different conditions of gas flow, inlet gas temperature, and steam parameters. In these calculations several trial — and-error steps are required before arriving at the final heat balance and duty, because the surface area is now known. The procedure is discussed for a simple case, configuration 1 of Fig. 8.4, which consists of a screen section, superheater, evaporator, and economizer.

1. Assume a steam flow Ws based on gas conditions.

2. Solve for the screen section, which is actually an evaporator, by using the methods discussed in Q8.15a.

|

FIgure 8.4 Configurations for water tube boiler. |

Solve for the superheater section, either using the NTU method or by trial and error. Assume a value for the duty and compute the exit gas/steam temperatures and then AT.

Assumed duty Qa = WgCp(Tg, — Tgo)hlf

= Ws(hso — hsi)

Where

Hso, hsi = enthalpies of steam at exit and inlet Tgi, Tgo = gas inlet and exit temperatures.

Compute U. Then transferred duty is Qt = U x A x AT. If Qa and Qt are close, then the assumed duty and gas/steam temperatures are correct; proceed to the next step. Otherwise assume another duty and repeat step 3.

4. Solve for the evaporator section as in step 1. No trial and error is required, because the steam temperature is constant.

5. Solve for the economizer as in step 3. Assume a value for the duty and then compute exit gas/water temperatures, AT, and Qt. Iteration proceeds until Qa and Qt match. The NTU method can also be used to avoid several iterations.

6. The entire HRSG duty is now obtained by adding the transferred duty of the four sections. The steam flow is corrected based on the actual total duty and enthalpy rise.

7. If the actual steam flow from step 6 equals that assumed in step 1, then the iterations are complete and the solution is over; if not, go back to step 1 with the revised steam flow.

The calculations become more complex if supplementary firing is added to generate a desired quantity of steam; the gas flow and analysis change as the firing temperature changes, and the calculations for U and the gas/steam temperature profile must take this into consideration. Again, if multipressure HRSGs are involved, the calculations are even more complex and cannot be done without a computer.

Determine the tube metal temperature for the case of a superheater under the following conditions:

Average gas temperature = 1200°F

Average steam temperature = 620°F

Outside gas heat transfer coefficient = 15 Btu/ft2h°F

Steam-side coefficient = 900 Btu/ft2 h °F

(Estimation of steam and gas heat transfer coefficients is discussed in Q8.03 and Q8.04.)

Tube size = 2 x 0.142 in. (2in. OD and 0.142 in. thick)

Tube thermal conductivity = 21 Btu/fth °F (carbon steel)

(Thermal conductivity of metals can be looked up in Table 8.9.)

Because the average conditions are given and the average tube metal temperature is desired, we must have the parameters noted above under the most severe conditions of operation—the highest gas temperature, steam temperature, heat flux, and so on.

Material 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

|

Aluminum (annealed)

|

(continued )

|

Temperature (°F)

|

Let us use the concept of electrical analogy, in which the thermal and electrical resistances, heat flux and current, and temperature difference and voltage are analogous. For the thermal resistance of the tube metal,

D d 2 ,2

= _ .,, ln — = ——— x ln ■

M 24Km ‘ d 24 x 21" ‘1.72

= 0.0006 ft2 h °F/Btu

Outside gas film resistance

Ro = = 0.067 ft2 h °F/Btu

12

Inside film resistance R, =—— = 0.0011 ft hr °F/Btu

‘ 900 ‘

Total resistance Rt 0.067 0.0006 0.0011

= 0.0687 ft2 h °F/Btu

Hence

1200 — 620 2 Heat flux Q = —0 0687— = 8443 Btu/ft h

Temperature drop across the gas film = 8443 x 0.067 = 565°F

Temperature drop across the tube metal = 8443 x 0.0006 = 5°F

Temperature drop across steam film = 8443 x 0.0011 = 9.3°F

(Here we have applied the electrical analogy, where voltage drop is equal to the product of current and resistance.) Hence,

* . (1200 — 565) + (620 + 9.3)

Average tube metal temperature =—————— 2—————— = 632 F

We note that the tube metal temperature is close to the tube-side fluid temperature. This is because the tube-side coefficient is high compared to the gas heat

Transfer coefficient. This trend would prevail in equipment such as water tube

Boilers, superheaters, economizers, or any gas-liquid heat transfer equipment.

An approximation of the tube metal temperature for bare tubes in a gasliquid or gas-gas heat transfer device is

Hi

Tm = to — , (to — ti) (35)

Hi + ho

Where

Ht, ho =heat transfer coefficients inside and outside the tubes, Btu/ft2h°F t,, to = fluid temperatures inside and outside, °F

In a boiler air heater, ho = 9, ht = 12, tt = 200°F, and to = 800°F. Estimate the average tube wall temperature tm.

Using Eq. (35), we have 12

Tm = 800 ————- x (800 — 200) = 457°F

M 12 + 9

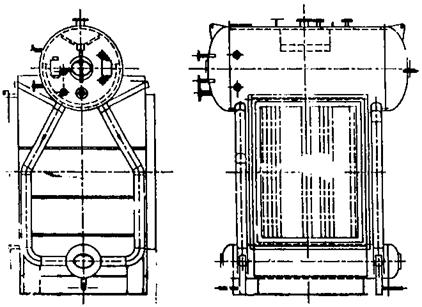

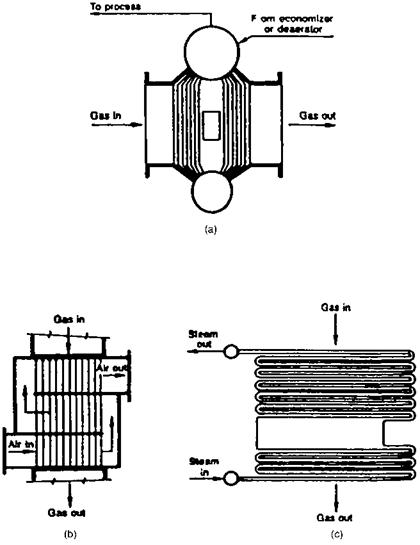

How is the performance of fire tube and water tube boilers evaluated? Can we infer the extent of fouling from operational data? A water tube waste heat boiler as shown in Fig. 8.5 Generates 10,000 lb/h of saturated steam at 300psia when the gas flow is 75,000 lb/h and gas temperatures in and out are 1000°F and 500°F. What should the steam generation and exit gas temperature be when 50,000 lb/h of gas at 950°F enters the boiler?

It can be shown as discussed in Q8.15a that in equipment with a phase change [1,8],

Ln t1 — tsat __ UA

T2 — tsat WgCp

Which was given there as Eq. (34).

For fire tube boilers, the overall heat transfer coefficient is dependent on the gas coefficient inside the tubes; that is, U is proportional to Wg, • 8. In a water tube boiler, U is proportional to Wg,• 6. Substituting these into Eq. (34) gives us the following.

|

FIgure 8.5 Sketch of (a) fire tube and (b) water tube boilers. |

For fire tube boilers:

|

H ~ ^si t9 tst |

|

Ln |

|

||

|

||

For water tube boilers:

|

T1 ~ ^sa To |

|

Ln |

|

|

|

|

As long as the fouling is not severe, Eqs. (36) and (37) predict the exit gas temperatures correctly. If t2 is greater than predicted, we can infer that fouling has occurred. Also, if the gas pressure drop across the boiler is more than the calculated value (see Chap. 7 for pressure drop calculations), we can infer that fouling has taken place.

Calculate K2 from Eq. (37). tsat = 417 from the steam tables (see the Appendix).

K2 = In f1000—417) x (75,000)° 4 = 173

2 500 — 417 7 ’

Let us predict the exit gas temperature when Wg = 50,000.

Ln (95° ~417) =^50’000^0 4 = 2.29 V t2 — 417 / 173

950 -417 t2 = 417 + ^29) = 471°F

Now the actual exit gas temperature is 520°F, which means that the fouling is severe.

The energy loss due to fouling is Q = 50,000 x 0.26 x (520 — 471)

= 0 . 63 x 106 Btu/h

If energy costs $3/MMBtu, the annual loss of energy due to fouling will be

3 x 0.63 x 8000 = $15,120 (assuming 8000 hours of operation a year).

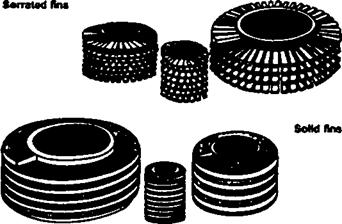

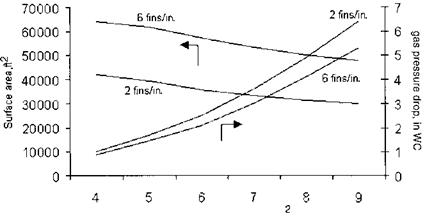

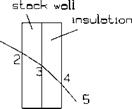

When and where are finned tubes used? What are their advantages over bare tubes?

Finned tubes are used extensively in boilers, superheaters, economizers, and heaters for recovering energy from clean gas streams such as gas turbine exhaust or flue gas from combustion of premium fossil fuels. If the particulate concentration in the gas stream is very low, finned tubes with a low fin density may be used. However, the choice of fin configuration, particularly in clean gas applications, is determined by several factors such as tube-side heat transfer coefficient, overall size, cost, and gas pressure drop, which affects the operating cost.

Solid and serrated fins (Fig. 8.6) are used in boilers and heaters. Finned surfaces are attractive when the ratio between the heat transfer coefficients on the outside of the tubes to that inside is very small. In boiler evaporators or economizers, the tube-side coefficient could be in the range of 1500- 3000Btu/ft2h °F, and the gas-side coefficient could be in the range of 10-

|

Figure 8.6 Solid and serrated fins. |

20Btu/ft2h °F. A large fin density or a large ratio of external to internal surface area is justified in this case. As the ratio between the outside and inside coefficients decreases, the effectiveness of using a large ratio of external to internal surface areas decreases. For example, in superheaters or high pressure air heaters, where the tube-side coefficient could be in the range of 30- 300Btu/ft2h °F, it does not pay to use a large fin surface; in fact, it is counterproductive, as will be shown later. A moderate fin density such as two or three fins per inch would be adequate, whereas for economizers or evaporators, five or even six fins per inch may be justified if cleanliness permits.

The other important fact to be kept in mind is that more surface area does not necessarily mean more energy transfer. It is possible, through poor choice of fin configuration, to have more surface area and yet transfer less energy. One has to look at the product of surface area and overall heat transfer coefficient and not at surface area alone. The overall heat transfer coefficient is significantly reduced as we increase the fin surface or use more fins per inch.

Finned tubes offer several advantages over bare tubes such as a compact design that occupies less space, lower gas pressure drop, lower tube-side pressure drop due to the fewer rows of tubes, and smaller overall weight and cost.

Solid fins offer slightly lower gas pressure drop than serrated fins, which have a higher heat transfer coefficient for the same fin density and configuration. Particulates, if present, are likely to accumulate on serrated finned tubes, which may be difficult to clean.

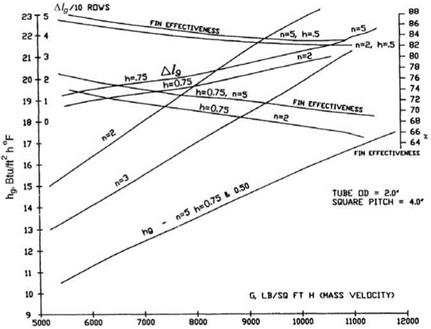

How are the heat transfer and pressure drop over finned tubes and tube and fin wall temperatures evaluated?

The widely used ESCOA correlations developed by ESCOA Corporation [9] will be used to evaluate the heat transfer and pressure drop over solid and serrated finned tubes in in-line and staggered arrangements. The basic equation for heat transfer coefficient with finned tubes is given by Eq. (3).

The calculation for tube-side coefficient ht was discussed earlier. ho consists of two parts, a nonluminous coefficient hN, which is computed as discussed in Q8.07, and hc, the convective heat transfer coefficient. Computation of hc involves an elaborate procedure and the solving of several equations, as detailed below.

Determination of Hc [9]

D + 2 h�• 5 fte + 460� • 25

TOC o "1-5" h z hc = C3 Ci C51 —-— x

D ) ta + 460

|

( |

!0 • 67

A) (38)

Wg

G = [(Sr/12) -Ao]NwL (39)

D nbh _ N

Ao = 12 + -6T (40)

C1; C2, and C3 are obtained from Table 8.10.

Gd

Re = 12m (41)

S =—— b (42)

n

Fin Efficiency and Effectiveness

For both solid and serrated fins, effectiveness z is

Af

Z = 1 -(1 — E) A (43)

C = 0 . 25 Re-035 C2 = 0 . 07 + 8Re-045 In-line

C3 = 0 . 2 + 0 . 65e-025h/s C4 = 0 . 08(0 .15ST/d)-11^ 15 C5 = 1.1 — (0 . 75 — 1. 5e-0. 7Nd)e-2 . 0SL/ST C6 = 1. 6 — (0 . 75 — 1. 5e-0. 7Nd)e-0 . 2(Sl/st)2 Staggered o 2o

C3 = 0.35 + 0.65e-0 . 25h/s C4 = 0 .11 (0 .15ST/d)-0 : 7(h/s)0 20 C5 = 0 . 7 + (0 . 7 — 0 . 8e-0 15Nd2)e-1 0SL/ST

C6 = 1.1 +(1. 8 — 2 .1 e-0 15Nd2)e-2 . 0(sl/st) — (0 . 7 — 0 . 8e-0 15Nd2)e-0 6(SL/Sr)

C1 = 0 . 25 Re-035 C2 = 0 . 07 + 8 . 0Re-0 45 In-line

C3 = 0 . 35 + 0 . 5e-035h/s C4 = 0 . 08(0 .15ST/d)-11(h/s)0 2 C5 = 1.1 — (0 . 75 — 1. 5e-0. 7Nd)e-2. 0SL/ST C6 = 1. 6 — (0 . 75 — 1. 5e-0 7wd)e-0.2(st/sr)2 Staggered

C3 = 0.55 + 0.45e-0 . 35h/s C4 = 0 .11 (0 . 05ST/d)-0 . 7(h/s)0 23 C5 = 0 . 7 + (0 . 7 — 0 . 8e-0 15Nd2)e-1 0SL/ST

C6 = 1.1 +(1. 8 — 2 .1 e-0 15Nd2)e-2. 0(sl/st) — (0 . 7 — 0 . 8e-0 15Nd2)e-0. 6(sl/st)

Source: Fintube Technologies, Tulsa, OK.

For solid fins,

|

Af = pn x—————— ————————————————————— (44) At = Af + p (45) |

4dh + 4h2 + 2bd + 4bh

4dh + 4h2 + 2bd + 4bh

^4"

D(1 — nb)

T2"

TOC o "1-5" h z E = 1/{1 + 0.002292 m2h2 [(d + 2h)/d]0 5} (46)

Where

M = (24ho /Kb)0 • 5 (47)

For serrated fins,

|

Af = pdn ———— ————— (48) |

![]() 2h(ws + b) + bws 12 ws

2h(ws + b) + bws 12 ws

At = Af + pd (1 12nb) (49)

E =tanh (mh) (50)

mh

C = 0 •053(1.45 — 2.9Sl/d)-2 • 3 Re-0 • 21 C2 = 0 .11 + 1.4 Re-0• 4

C3 = 0 •20 + 0. 65e-025h/s C4 = 0 . 08(0 .15ST/d)-11(h/s>0 15

C5 = 1.1 — (0 . 75 — 1. 5e-0• 7Nd)e-2• 0Sl/st c6 = 1. 6 — (0 . 75 — 1.5e-0 • 7Nd)e-0 • 2(Sl/st)2

J = C C3C5[(d + 2h)/d]0 5[(tg + 460)/(ta + 460)]° 5 f = C2C4C6[(d + 2h)/d][(tg + 460)/(ta + 460)]0 • 25 Staggered

C1 = 0 . 091 Re-0 • 25 C2 = 0.075 + 1.85 Re-0 • 3 o 2o

C3 = 0.35 + 0. 65e-025h/s C4 = 0 .11 (0 . 05ST/d)[4]

|

-°-6(Sl/St ) |

![]() C5 = 0 . 7 + (0 . 7 — 0 . 8e-0 15Nd2)[e-10SL/ST] C6 = 1.1 +(1. 8 — 2 .1 e-0 15Nd2)e-2 0(SL/ST> — [0 . 7 — 0 .8e-0 •15N2]e~

C5 = 0 . 7 + (0 . 7 — 0 . 8e-0 15Nd2)[e-10SL/ST] C6 = 1.1 +(1. 8 — 2 .1 e-0 15Nd2)e-2 0(SL/ST> — [0 . 7 — 0 .8e-0 •15N2]e~

J = C1 C3C5[(d + 2h/d]05[(fg + 460)/(ta + 460)]05

F = C2C4C6[(d + 2h)/d]0 • 5[( tg + 460)/( ta + 460)]-0 • 25

C1 = 0.053(1.45 — 2.9Sl/d)-2 • 3 Re-0 • 21 C2 = 0 .11 + 14 Re-0 • 4

C3 = 0 . 25 + 0 . 6e-026h/s C4 = 0 . 08(0 .15ST/d)^•H^)015

C5 = 1.1 — (0 . 75 — 1. 5e-0• 7Nd)e-2 • 0SL/ST C6 = 1. 6 — (0 . 75 — 1.5e-0 • 7Nd)e-0 • 2(Sl/st)2

J = C1 C3C5[(d + 2h)/d]0 5[( tg + 460)/( ta + 460)]0 5 f = C2C4C6[(d + 2h)/d][(tg + 460)/(ta + 460)]0 • 25 Staggered

C1 = 0 . 091 Re-0 • 25 C2 = 0.075 + 1.85 Re-0 • 3 o

C3 = 0 •35 + 0. 65e-0 17h/s C4 = 0 .11 (0 . 05ST/d)2

|

°:6(Sl/St ) |

![]() C5 = 0 • 7 + (0 . 7 — 0 . 8e-0 15Nd2)e-10SL/st C6 = 1.1 +(1. 8 — 2 .1 e-0 15Nd2)e-2 0(SL/ST) — (0 .7 — 0 .8e-0 15Nd2)e-

C5 = 0 • 7 + (0 . 7 — 0 . 8e-0 15Nd2)e-10SL/st C6 = 1.1 +(1. 8 — 2 .1 e-0 15Nd2)e-2 0(SL/ST) — (0 .7 — 0 .8e-0 15Nd2)e-

J = C CsCsKd + 2h)/d]° :5[(fg + 460)/(fa + 460)]° 25 f = C2C4C6[(d + 2h)/d]° ■ 5[(fg + 460)/(fa + 460)]-° ■ 25

Where

Kbws

Gas pressure drop APg is

DPg = (f + a) Pg x 1.083d X 109 (52)

Where

2h 0 5

TOC o "1-5" h z f = C2C4C6 x ^—-—J for staggered arrangement (53)

D ~)- 2h

= C2C4C6 x—— — for in-line arrangement (54)

D

1 + B2 tg2 — tgi

A 4Nd X 4(50 + tg (55)

B = ffree gaS areaV (56)

total area /

C2, C4, C6 are given in Table 8.10 for solid and serrated fins.

Tube Wall and Fin Tip Temperatures

For solid fins the relationship between tube wall and fin tip temperatures is given

By

TOC o "1-5" h z tg — tf = K1(mre) x I0(mre) + I1(mre) X K0(mre) (57)

Tg — tb Ki(mre) x Io(mro) + Ko(mr0) x ^1 (mre)

The various Bessel functional data are shown in Table 8.11 for serrated fins, treated as longitudinal fins:

Tg — tf 1

Tg—f = (58)

Tg — tb cosh(mb)

A good estimate of tf can also be obtained for either type of fin as follows:

Tf = tb + (tg — tb) x (1. 42 — 1. 4 E) (59)

Tb, the fin base temperature, is estimated as follows:

Tb = ti + q (R3 + R4 + R5) (60)

Where R3, R4, and R5 are resistances to heat transfer of the inside film, fouling

Layer, and tube wall, respectively, and heat flux qo is given by

Q0 = Uo(tg-1,) (1)

The following example illustrates the use of the equations.

|

X |

Wx) |

/1(x) |

K)(x ) |

K1(x) |

|

0 |

1.0 |

0 |

8 |

8 |

|

0.1 |

1.002 |

0.05 |

2.427 |

9.854 |

|

0.2 |

1.010 |

0.10 |

1.753 |

4.776 |

|

0.3 |

1.023 |

0.152 |

1.372 |

3.056 |

|

0.4 |

1.040 |

0.204 |

1.114 |

2.184 |

|

0.5 |

1.063 |

0.258 |

0.924 |

1.656 |

|

0.6 |

1.092 |

0.314 |

0.778 |

1.303 |

|

0.7 |

1.126 |

0.372 |

0.66 |

1.05 |

|

0.8 |

1.166 |

0.433 |

0.565 |

0.862 |

|

0.9 |

1.213 |

0.497 |

0.487 |

0.716 |

|

1.0 |

1.266 |

0.565 |

0.421 |

0.602 |

|

1.2 |

1.394 |

0.715 |

0.318 |

0.434 |

|

1.4 |

1.553 |

0.886 |

0.244 |

0.321 |

|

1.6 |

1.75 |

1.085 |

0.188 |

0.241 |

|

1.8 |

1.99 |

1.317 |

0.146 |

0.183 |

|

2.0 |

2.28 |

1.591 |

0.114 |

0.140 |

|

2.2 |

2.629 |

1.914 |

0.0893 |

0.108 |

|

2.4 |

3.049 |

2.298 |

0.0702 |

0.0837 |

|

2.6 |

3.553 |

2.755 |

0.554 |

0.0653 |

|

2.8 |

4.157 |

3.301 |

0.0438 |

0.0511 |

|

3.0 |

4.881 |

3.953 |

0.0347 |

0.0402 |

|

3.2 |

5.747 |

4.734 |

0.0276 |

0.0316 |

|

3.4 |

6.785 |

5.670 |

0.0220 |

0.0250 |

|

3.6 |

8.028 |

6.793 |

0.0175 |

0.0198 |

|

3.8 |

9.517 |

8.140 |

0.0140 |

0.0157 |

|

4.0 |

11.30 |

9.759 |

0.0112 |

0.0125 |

|

4.2 |

13.44 |

11.70 |

0.0089 |

0.0099 |

|

4.4 |

16.01 |

14.04 |

0.0071 |

0.0079 |

|

4.6 |

19.09 |

16.86 |

0.0057 |

0.0063 |

|

4.8 |

22.79 |

20.25 |

0.0046 |

0.0050 |

|

5.0 |

27.24 |

24.34 |

0.0037 |

0.0040 |

A steam superheater is designed for the following conditions.

Gas flow = 225,000 pph Gas inlet temperature = 1050°F Gas exit temperature = 904°F

Gas analysis (vol%): CO2 = 3, H2O = 7, N2 = 75, O2 = 15

Steam flow = 50,000 pph Steam temperature in = 501°F (sat)

Steam exit temperature = 758°F Steam pressure (exit) = 650 psig