Dust collection in a boiler plant is mainly for the control of the particulate emissions, and the separated dust is disposed of by a suitable ash-handling system. In some cases, part (stoker, BFBC) or all (CFBC) of the dust is required to be returned to the system to enhance the combustion efficiency. In CFBC boilers, the main process is dependent on the returned dust, which acts as a coolant in the bed. Cyclones in CFBCs are actually used as process equipment. The cyclone evaporator and the Venturi scrubber in BL-fired boilers help to concentrate the liquor in addition to trapping the dust.

Besides meeting the required particulate level, the dust-collection equipment is also required to comply with the specified opacity limit. Opacity is the measure of clearness of stack. A beam of light is passed through the flue gases to determine how much dust is either absorbed or scattered. This is usually —20%.

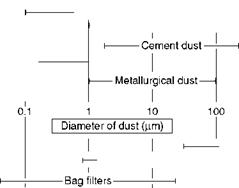

The particulates in boiler gases can be of various sizes and can be classified as dust, smoke, fumes, and mist, based on decreasing particle diameter. Different types of dust catchers are required for different types of dust, as shown in Figure 8.26. Besides the size or particle diameter, properties such as the electrical and chemical characteristics, surface — to-volume ratio, particle density, and rates of settling under gravity are some of the factors that influence the choice and sizing of the collecting equipment.

In almost every type of combustion, ash is elutriated with flue gases, resulting in fly ash, which needs to be collected to keep the stack clean. The amount of fly ash varies with the fuel, type of combustion, amount of ash in fuel, etc. Natural gas (NG) firing produces no fly ash. Pulverized fuel, however, generates —80% fly ash. In the case of CFBC, the fly ash is more than —90% and is accompanied by considerable quantities of CaSO4. Stokers produce 10-40% fly ash with a lot of coarse particles. Table 8.1 summarizes the type

|

10 -Pulverized coal I i————————— Stoker fly ash |

|

100 I, |

|

1000 |

|

Wet scrubbers |

|

_L |

|

Collection methods —— 1————— H 1 10 |

|

0.001 FIGURE 8.26 Overview of various types of dust and collectors. |

|

0.01 |

|

0.1 |

|

|

|

||||

|

||||||

|

||||||

|

|

|||||

|

|

|||||

|

||||||

|

||||||

|

||||||

|

||||||

|

|

|

||||

|

TABLE 8.1 Fly Ash in Various Firing Modes in Coal Firing

|

Of ash generated in each type of firing. The dust-collecting equipment in a boiler can be classified as

• MDCs

• ESP or electrofilters

• Bag or FFs

• Wet or liquid scrubbers

Particles larger than 100 |jm (0.1 mm) settle quickly and may need no more than settling chambers. In any case, boiler ash is always finer than 100 |jm.

Gas and dust are worked on differently. In MDCs, the gas is given a change of direction by centrifugal action. Naturally, this takes a lot of energy as compared with the ESPs where only the dust is treated. The gases are not treated in ESPs. In bag filters, however, the gas is worked on, as the dusty gases are filtered through the cloth separator. Naturally, energy expended is considerable. In wet scrubbers, the gas is sprayed with water to capture the dust.

29 августа, 2013

29 августа, 2013  admin

admin  Опубликовано в рубрике

Опубликовано в рубрике