Depending on the collection process, MDCs can be classified as

• Inertial separators

• Centrifugal separators

Inertial separators rely on a change of direction of gas flow or interception of dust or both, to effect a separation of dust particles from gas. They are simple in construction with low pressure drop and moderate collection efficiencies. They are essentially good for collecting grit from flue gases for refiring. U-beams in CFBCs and deflection baffles in hoppers are typical examples of inertial separators.

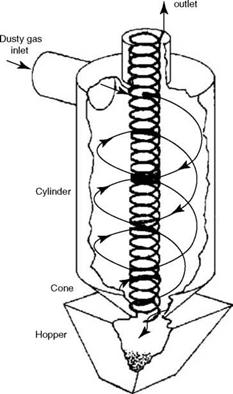

Centrifugal or cyclone separators provide a downward high-speed swirl to the gases, causing the dust particles to be thrown to the periphery by the centrifugal action, and slide down along the edge. The inward inclination of the collector tube at the discharge end helps the gases to form a smaller swirl inside and exit at the top duly dedusted. This is explained in Figure 8.27. Depending on the gas volume and the dust loading, the cyclones can be classified as

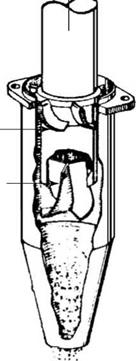

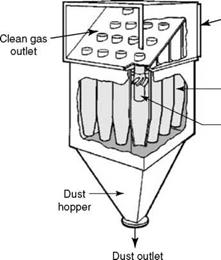

• Small-diameter multicyclones, also called multiclones (Figures 8.28 and 8.29)

• Large-diameter cyclones arranged in single or multiple units (Figure 8.27)

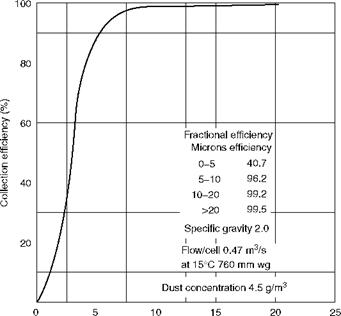

Multiclones employ small-diameter (250-500 mm mostly) long tubes, which help to provide higher centrifugal forces and longer separation time, both of which increase the collection efficiency, which can be as high as 95% for particles larger than 5 |jm under

|

Clean gas

|

FIGURE 8.27

Large-diameter cyclone separators.

Steady conditions, as can be seen in Figure 8.30. The individual collection tube assemblies (Figure 8.28) are made of white cast iron (CI) or Ni-hard with hardness of —400 BHN, offering a fairly long life even with very abrasive dust. The limitations of multiclones are as follows:

• The performance is seriously affected by load swings and fuel and ash characteristics.

• Opacity standards cannot be met, as the particles below 5 |jm escape with the gases.

• The pressure drop is high, typically between 50 and 125 mm wg.

The advantages of multiclones are

• Simplicity of construction

• Compactness

• Low initial cost

• Minimal maintenance

• Low running cost

|

|

|

Stationary inlet guide vanes Recovery Vanes |

|

Clean gas JL- |

|

Outlet Tube |

|

: Dust outlet |

FIGURE 8.28

Small-diameter cyclones used in multiclones.

|

|

|

Dirty gas inlet |

|

Cyclone Tube Outlet Tube |

FIGURE 8.29

Multiclones.

|

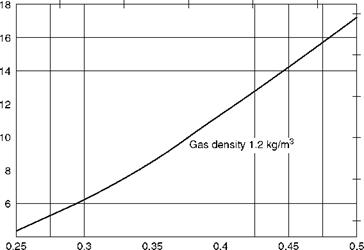

Particle size (|xm) FIGURE 8.30 Typical collection efficiency of multiclone. |

The main disadvantages are

1. Poor collection efficiencies for particles below 5 |jm size (Figure 8.30), which do not meet the present-day opacity and particulate pollution norms.

2. With high inlet dust loading, the small inlets of the cyclones get choked, making the multiclones unsuitable.

A typical volume versus pressure drop relationship is shown in Figure 8.31.

The multiclones are now practically obsolete because of the present-day pollution norms for particulate emission. They are now occasionally used as precollectors before the ESPs or bag filters to trap the grits in the dust for refiring purposes.

In the 1960s and 1970s, they were used as precollectors to the ESPs with a view to reducing the dust load on ESPs to improve the collection and reduce the size. These expectations were belied because the ESP sizing depended more on the collection of fines and not so much on the grit.

These cyclones, ranging from <1 m to more than 10 m in diameter, are employed for higher dust loads and gas volumes. Also, they can be adapted for higher temperatures of ~900°C and high erosion by lining the inside walls. The interest in cyclones is now sustained by their use in the CFBC boilers.

|

|

|

A -Q JE CL O ■o Њ |

|

(D □L |

|

600 |

|

700 |

|

Volume /cell (cfm) 800 |

|

900 |

|

1000 |

|

Volume/cell (m3/s) |

|

FIGURE 8.31 Volume/cell versus pressure drop. |

|

O ■o Њ |

|

2 □l |

|

4 |

Large-diameter cyclones are also used in boilers firing biomass if the emission standards are not as stringent, as the dust loads are low due to low ash content of fuel. Multiclones with their characteristic high gas velocities are unsuitable for ash of biofuels, which is usually very light and hence has a tendency for re-entrainment.

29 августа, 2013

29 августа, 2013  admin

admin

Опубликовано в рубрике

Опубликовано в рубрике